Keeping warehouse spaces clean isn’t just about appearances; it’s about safety, efficiency, and the health of people and goods. Over the past few years, attention to sanitation in industrial settings has grown. Global health concerns, stricter regulations, and customer expectations drive them. Today, best practices include smart cleaning schedules, data‑driven inspections, and hygiene-focused engineering. Adopting up-to-date hygiene protocols is non-negotiable, whether you’re managing food, pharmaceuticals, automotive parts, or general merchandise.

This guide presents seven enhanced hygiene tips for 2025, grounded in proven strategies from industry leaders. We’ll look at how technology and tools now support more innovative hygiene management, offer a practical warehouse hygiene checklist, address pest control and equipment cleaning, and close with actionable next steps. These hygiene tips for warehouses blend simple habits with optimized systems, showcasing why hygiene isn’t just a task; it’s a mindset woven into every workflow.

Technology and Tools to Support Warehouse Hygiene

Technology plays a massive role in transforming how hygiene is managed. What used to be manual and inconsistent is now competent, trackable, and far more reliable. When paired with human effort, these tools enhance consistency. Integrating technology is among the most effective hygiene tips for warehouses today, especially for large or multi-shift operations.

- Sensor-based dispensers: These track sanitizer usage and send alerts when refills are low, helping you ensure supplies are always stocked.

- Automated floor cleaners: Robotic scrubbers are now used in many warehouses to clean large floor spaces at scheduled intervals.

- UV-C disinfection systems: Portable UV lights sanitize high-risk areas like packing stations and shared devices.

- Digital checklists: Apps like SafetyCulture or iAuditor allow managers to monitor real-time hygiene compliance. You can assign tasks, collect photo proof, and keep digital audit logs.

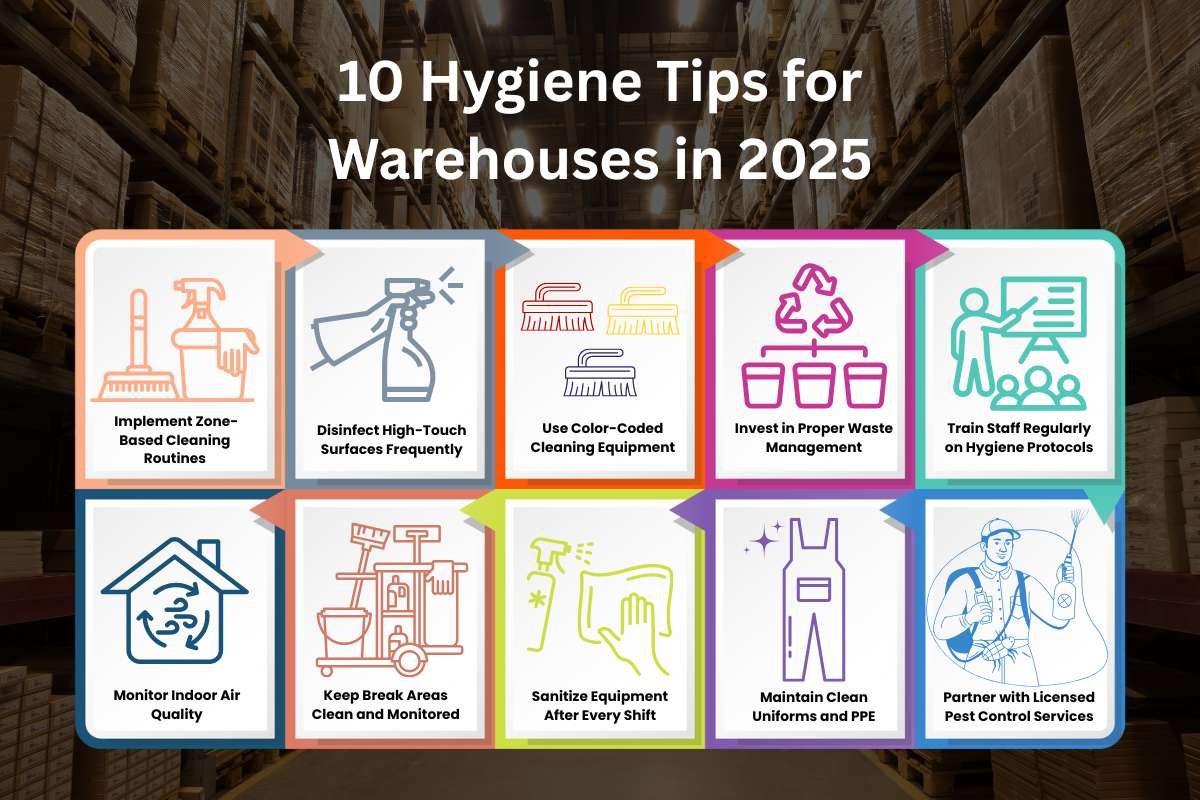

10 Hygiene Tips for Warehouses in 2025

1. Implement Zone-Based Cleaning Routines

Not every area of a warehouse requires the same level of cleaning. Create zones, like receiving, storage, dispatch, break areas, and restrooms, and design cleaning schedules based on traffic and risk. High-traffic areas should be cleaned multiple times daily. Clear zoning avoids overlap, assigns accountability, and maintains hygiene without disrupting productivity.

2. Disinfect High-Touch Surfaces Frequently

Areas such as forklift handles, control panels, scanner guns, and door handles are breeding grounds for germs. These should be disinfected multiple times a day. Encourage staff to wipe down tools before and after every use. Use fast-drying, non-toxic disinfectants that don’t leave residue or damage electronic parts. This is among the most practical and often overlooked Hygiene Tips for Warehouses.

3. Use Color-Coded Cleaning Equipment

Assign specific colors for mops, cloths, and buckets based on area types.

For instance:

- Blue for general areas

- Red for restrooms

- Green for food or break rooms

- Yellow for equipment

This prevents cross-contamination and helps workers quickly identify the correct tools. Make sure the color code chart is displayed in the cleaning storage rooms.

4. Invest in Proper Waste Management

Overflowing bins or uncovered waste areas attract pests and create unpleasant odors. Place sealed bins throughout the warehouse and establish a strict collection schedule.

Use heavy-duty, easy-to-clean bins with lids. Monitor garbage zones using checklists. These simple steps are foundational hygiene tips for warehouses and contribute to safer, clutter-free paths for forklifts and trolleys.

5. Train Staff Regularly on Hygiene Protocols

Training should be more than just a once-a-year slideshow. Create regular hygiene refreshers during morning briefings or safety meetings. Make it interactive. Use demonstrations, posters, and real warehouse scenarios. Hygiene awareness starts with the people on the floor.

Topics can include:

- Proper handwashing techniques

- PPE usage and disposal

- Sanitizing shared equipment

- Cough/sneeze etiquette

6. Monitor Indoor Air Quality

Poor ventilation can lead to dust buildup, respiratory issues, and increased bacteria. Ensure that HVAC systems are serviced every quarter and filters are replaced regularly.

You don’t need cutting-edge systems; simple practices like opening dock doors during downtime or adding mobile air purifiers in closed spaces help maintain air hygiene.

7. Keep Break Areas Clean and Monitored

Break rooms can quickly become messy, especially during peak hours—place reminders for employees to clean up after themselves. Assign a designated person per shift to oversee the break area hygiene.

Install automatic soap and sanitizer dispensers, and avoid shared utensils. Include this space in your routine hygiene audits. Clean break areas reflect how seriously your warehouse takes hygiene.

8. Sanitize Equipment After Every Shift

Forklifts, carts, and pallet jacks often change hands between shifts. Require operators to sanitize these tools using wipes or sprays at the end of their shift.

Create a simple logbook where each operator signs off that they’ve cleaned their equipment. These small habits are highly effective Hygiene Tips for Warehouses, especially when multiple users handle the same machinery.

9. Maintain Clean Uniforms and PPE

Dirty uniforms can carry contaminants from outside into your warehouse floor. Encourage staff to wear freshly laundered uniforms daily and offer laundry support.

If your team uses gloves, masks, or shoe covers, monitor their usage closely. Reusable PPE should be cleaned after each use, while disposable PPE should be discarded properly.

10. Partner with Licensed Pest Control Services

No warehouse is completely pest-proof. Regular pest control checks, bait stations, and sealed food storage can reduce risk significantly. Log every inspection and treatment to keep track.

Combine professional services with good hygiene practices, like clearing cardboard boxes, sealing entry points, and cleaning under shelves. Pest management is one of the most business-critical hygiene tips for warehouses, especially in the food and pharmaceutical sectors.

Warehouse Hygiene Checklist

To maintain all of the above, create a hygiene checklist categorized into:

- Daily tasks: Surface disinfection, waste bin checks, and restroom cleaning.

- Weekly tasks: Deep clean high-traffic zones, equipment sanitation, pest spot checks.

- Monthly tasks: Ventilation audits, PPE stock review, hygiene retraining sessions.

Use digital tools to assign and track completion. Display a printed copy on every warehouse board as a backup. The checklist builds accountability and ensures hygiene isn’t treated as an afterthought.

Pest Control and Equipment Care

Beyond surface cleanliness, long-term hygiene relies on two things: pest control and equipment hygiene.

Pest Control

- Schedule bi-monthly visits by licensed professionals.

- Eliminate food sources (crumbs, spills, open packaging).

- Place rodent traps discreetly near entrances and dark corners.

- Repair cracks and seal drain lines to prevent entry.

Equipment Care

- Train staff to sanitize gear like barcode scanners, label printers, and tablets.

- Set up “cleaning stations” stocked with wipes and disinfectant.

- Keep machines dust-free to avoid clogging and bacterial growth.

- Have machines serviced quarterly to maintain both function and hygiene.

Conclusion

Warehouse hygiene is not just a compliance issue; it’s a culture. Every tip shared above plays a small part in building that culture, from innovative technology to daily routines. When staff feel safe, tools stay clean, and products remain uncontaminated, the benefits ripple across every part of your operation.

Start with what you can control today. A checklist, a better training system, and a stricter break room routine are simple ways to apply these hygiene tips for warehouses. In time, what begins as a task becomes a habit, and what becomes a habit shapes your success.