The dynamic technological and geopolitical landscapes are constantly blazing new trails in the aerospace and defense manufacturing industry. Thus far, the industry has seen major advancements, particularly with the rise of artificial intelligence, robotics, material science, and additive manufacturing. In this post, discover the emerging trends and innovations poised to continuously redefine national security, global transportation, and space exploration.

Trends And Innovations Of Aerospace And Defense Manufacturing:

1. Advanced Materials Enhance Structure

One of the key trends shaping the future of aerospace and defense manufacturing is the emergence of advanced materials. Traditional metals, such as aluminum and titanium, are being supplemented and, in some cases, replaced by lightweight composites and alloys.

Advanced materials with superior strength-to-weight ratios—such as carbon fiber composites, titanium alloys, and ceramic matrix composites—are revolutionizing aerospace and defense manufacturing. These materials offer exceptional strength, stiffness, and thermal properties while maintaining low weight. These qualities make them ideal for critical aerospace components like aircraft structures, engines, and thermal protection systems.

The widespread adoption of these materials is driving advancements in aircraft performance, fuel efficiency, and sustainability. Companies like BFS Manufacturing are on the leading edge of working with these advanced materials.

Furthermore, advancements in material science, including nanomaterials and metamaterials, are opening up new possibilities for next-generation aircraft and defense systems.

2. Additive Manufacturing Transforms Production

Additive manufacturing, commonly known as 3D printing, is already being used to fabricate aircraft and spacecraft parts. In fact, NASA is exploring the use of 3D printing to construct spacecraft and planetary habitats with in-situ resource utilization.

As this technology matures, additive manufacturing will become ubiquitous in aerospace and defense manufacturing sectors for rapid prototyping, production of low-volume parts, and creation of intricately designed and optimized components that are impossible to produce with subtractive methods alone.

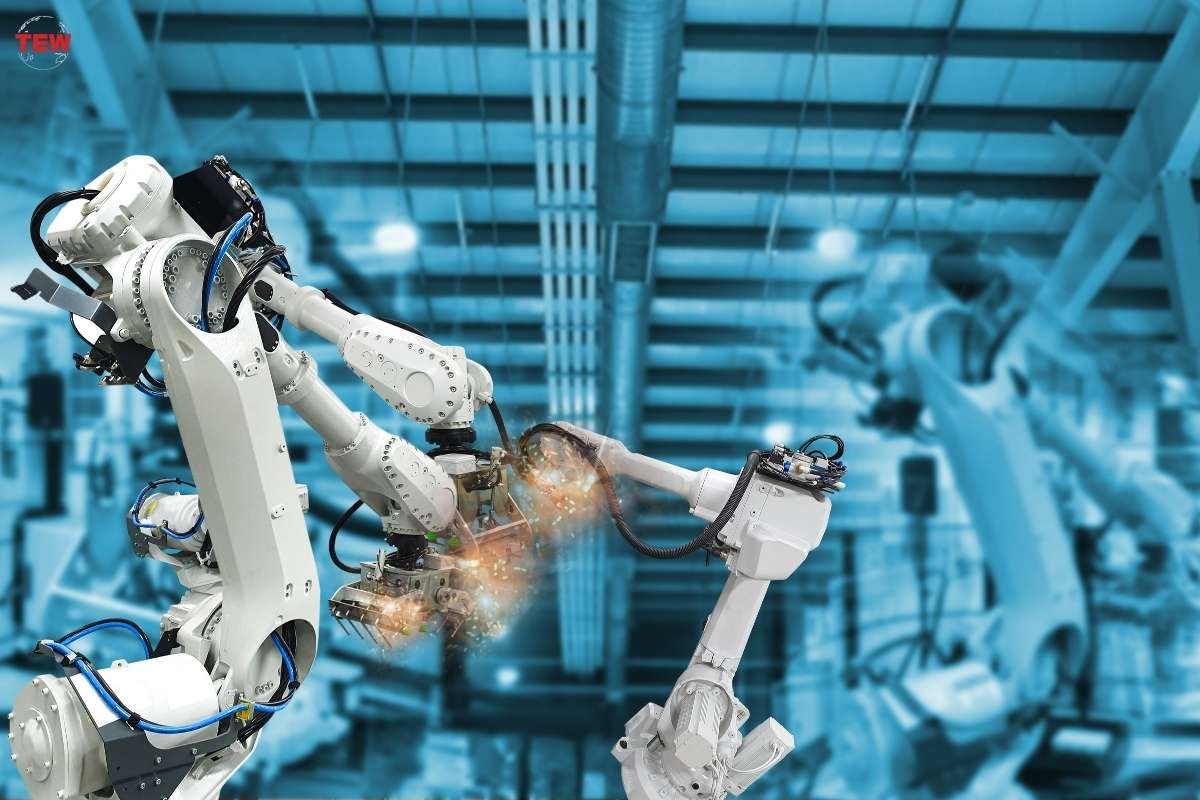

3. Automation And Robotics Boost Efficiency

Automation and advanced robotics are also gaining traction on the factory floor. Human workers still reign supreme for specialized tasks like aircraft assembly. However, collaborative robots can work safely alongside people while automating dangerous yet repetitive jobs. Automation boosts manufacturing precision and efficiency as well.

Other major defense companies are increasing their use of intelligent robotics for cutting, welding, painting, moving materials, and quality control. Higher levels of automation will likely be a hallmark of the factories of tomorrow.

4. Connected Factories Enable Data-Driven Decisions

Connected manufacturing mainly leverages Industrial Internet of Things (IIoT), big data analytics, and artificial intelligence (AI). Networked sensors feed system-wide data to predictive analytics algorithms. These sensors give managers unprecedented visibility into equipment health, inventory levels, supply chain flows, and more.

AI augments human decision-making to catch production issues before they become problems. It also enables processes to self-optimize based on continuous inbound data. The long-term vision is an autonomic factory that dynamically adjusts workflows to maximize efficiency and output quality.

5. NewSpace Disrupts Aerospace Markets

The New Space Age refers to the involvement of private sectors in creating ripples in space exploration. Thus, nontraditional manufacturing firms also bear watching in the defense sphere. Elon Musk’s SpaceX, for example, has disrupted the space launch services market with pivotal innovations, like reusable first-stage boosters. Spurred by commercial goals, SpaceX iterates and innovates at speeds yet impossible for traditional defense contractors to sustain.

As this NewSpace philosophy spreads, it could reshape militaries’ access to space-enabled capabilities. Adopting commercial best practices in manufacturing agility, cost-consciousness, and rapid testing could strengthen national security space efforts.

6. Sustainability Becomes Imperative

Sustainable manufacturing will continue growing in importance. The defense industry is one of the major consumers of energy and material resources. Crucial processes like forging, casting, welding, and painting of military assets require huge inputs of carbon-based power. These assets have long lifecycles, so small energy and material efficiency gains multiply over decades.

Transitioning to renewable energy, optimizing material flows, reducing waste, and recycling and reusing components will help defense and aerospace manufacturers achieve cost and sustainability targets. It also makes operations more resilient against energy supply disruptions.

7. Emerging Innovations Shape Future Possibilities

Other nascent technologies show promise for revolutionizing defense production down the road. Quantum computing can massively accelerate optimization tasks like scheduling and logistics. Blockchain could enhance transparency and traceability across global supply chains. Hypersonic flight could open new operational possibilities that would require specialized design and manufacturing expertise to realize. Progress in nanotechnology, energetics chemistry, and cognitive science may yield new materials, propellants, and autonomous systems to power future capabilities.

8. Adaptability And Partnerships

In a fast-moving R&D landscape, agility and adaptability will become more vital. Companies must keep abreast of technical developments and market demands to capitalize on innovation opportunities.

Partnerships with research institutions, startups, and tech firms also help expand technological horizons. Visionary leadership will also help set the stage for transformative leaps like defect-free digital manufacturing and full-stack data analytics.

9. Manufacturing Excellence Underpins Strategic Edge

With the right digital investments and partnerships, manufacturers of aerospace and defense manufacturing can leverage cutting-edge techniques to increase efficiency, resilience, and competitiveness. The coming wave of innovation looks set to shape the next generation of manned and crewless aircraft, missile defense assets, space systems, and multifunction platforms that give countries an operational edge. Manufacturing advances underpin the fielding of novel capabilities that tilt the strategic balance. So industry and military leaders must plan wisely to secure technological leadership through manufacturing excellence.