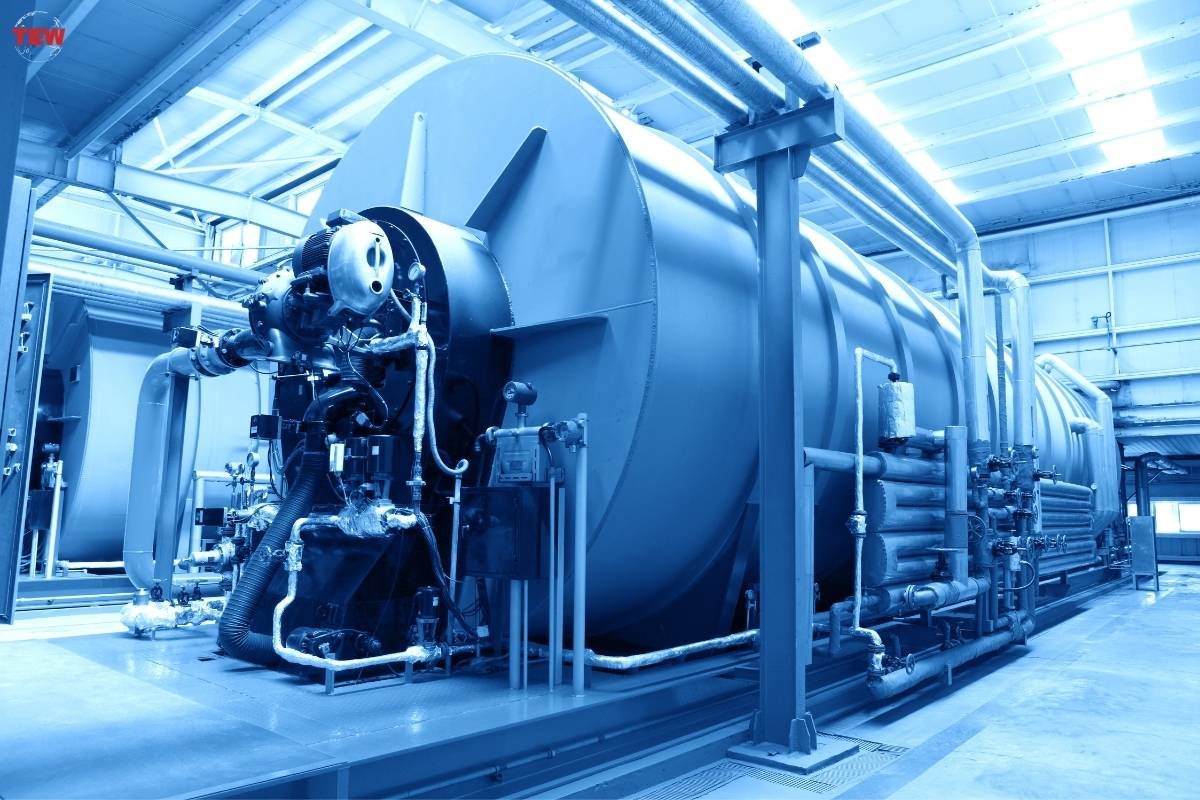

The boiler industry was once relatively static. But it has undergone a profound transformation in recent years. Credit goes to technological advancement as well as the mounting environmental concerns.

The global boiler market is anticipated to grow from $85 billion in 2022 at a CAGR of 7.73% to $179 billion by 2032. The growing demand for energy-efficient systems is one factor that will drive the market growth. Stringent government rules to reduce carbon emissions will also contribute to market growth.

As demands for sustainability, efficiency, and reliability escalate, boiler manufacturing is embracing cutting-edge technologies to revolutionize traditional heating systems.

Here, we’ll explore the latest boiler manufacturing that is heating up the market:

1. AI-Integrated Boilers

Artificial intelligence has been a hot topic in recent years. It has permeated every aspect of our daily lives.

From refrigerators that can create grocery lists to thermostats that learn our preferences, the concept of “smart” technology has revolutionized how we interact with our homes. It was inevitable, then, that boilers, the traditional workhorses of home heating, would also undergo a transformation.

The latest models are now integrated with AI to forecast demand, monitor usage patterns, and adjust performance in real-time. Integration of AI into boilers has improved efficiency, optimized energy usage, and enhanced overall performance.

Another advantage of AI integration in boilers is predictive maintenance. AI algorithms can detect patterns indicative of potential issues by analyzing data from sensors and monitoring the performance of boilers. Anomalies detected early on allow users to take proactive action before the issue escalates. This enhances the longevity of boilers.

2. Low Mass Boilers

Low mass models—a convenient alternative to traditional boilers—have emerged to be a game-changer in the realm of heating systems.

Unlike traditional boilers, which often feature bulky heat exchangers with large water volumes, low-mass boilers utilize innovative designs and materials to minimize mass and maximize surface area.

These boilers are lightweight in design and compact in size. This makes them ideal for installations where space is limited. Low mass boilers feature a small holding tank as well as small diameter pipes to heat water rapidly. Due to such a design, these boilers are highly efficient and reduce fuel consumption. This helps lower heating bills.

Low mass boilers typically run on coal, oil, or gas. You should, however, choose boilers that use oil to heat water and rooms. Not only do these significantly reduce greenhouse emissions, but they also offer energy efficiency benefits.

Oil heat boilers, drawing on expertise shared by high-efficiency oil boiler manufacturer Energy Kinetics, provide the highest comfort in old or new homes with inexpensive operation. Besides, these offer quick recovery from thermostat night setbacks and practically unlimited hot water with well-integrated tank storage systems.

3. Carbon-Neutral Boilers

Carbon-neutral boilers are one of the most groundbreaking inventions of 2023. These boilers use renewable energy resources to heat water, which in turn heats the building.

Biofuels, biomass, or hydrogen are used as primary fuels in carbon-neutral boilers. Due to this, the greenhouse emissions of these boilers are low.

The initial installation cost of carbon-neutral boilers might be high, but operating costs are low. Renewable fuels such as biofuels or biomass are generally cheaper and more stable in price compared to fossil fuels, which are subject to market fluctuations. If you choose a carbon-neutral boiler, you will save a significant sum on fuel expenses.

4. Hybrid Boiler Systems

A hybrid boiler system combines the best of multiple heating technologies to maximize efficiency and versatility. These systems typically combine a traditional boiler with a renewable system, such as a ground or air-source heat pump. A hybrid boiler switches between the two automatically for maximum efficiency.

On sunny days, for instance, the system may rely more on solar energy, but during gloomy or high-demand periods, it may return to the traditional boiler. This seamless transition maximizes energy efficiency while ensuring uninterrupted heating,

Hybrid systems are ideal for all seasons. They will keep your home warm throughout winter and cool during summer. The installation costs of hybrid boiler manufacturing systems are high. But they can lead to considerable savings since the traditional boiler system won’t be needed much. Your requirements for gas or oil will, thus, be low.

To sum things up, the landscape of boiler manufacturing is characterized by a wave of innovation and technological advancement that is reshaping the industry.

From AI-integrated boilers that optimize performance to carbon-neutral boilers leading the charge toward sustainability, these breakthroughs are driving unprecedented efficiency in domestic and industrial heating systems. With these latest innovations, manufacturers are poised to meet current challenges and lead the way toward a more efficient, sustainable, and resilient future.