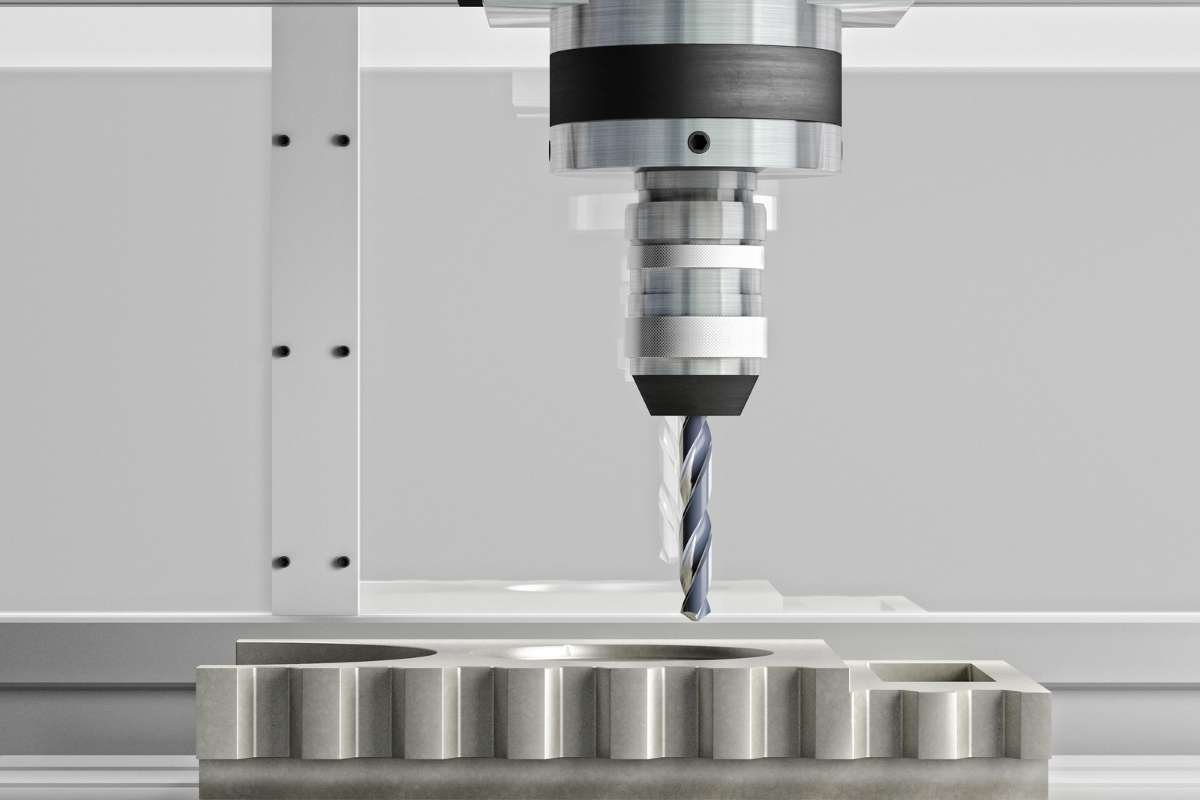

Picking the right CNC drilling service can feel overwhelming, but it doesn’t have to be. Whether you’re working on a large-scale manufacturing project or a one-off custom piece, the service you choose will directly impact the quality and success of your work. With so many options out there, how do you narrow it down to the perfect fit for your needs? Read on to learn more.

1. Know What Your Project Requires

Before you even start looking for a CNC drilling service, you’ve got to know what you need. Ask yourself:

- What materials will be drilled? Aluminum, steel, plastics, or composites?

- What level of precision is required?

- Are there any specific tolerances or finishes needed?

- How many parts or units will you need?; and so on.

By answering these questions, you’ll have a clear understanding of your project’s scope. This will save you time and help you communicate effectively with potential service providers.

2. Look Into The Company’s Expertise

Experience matters when it comes to CNC drilling. Look for a service with a solid track record in your industry. A provider that’s familiar with your specific materials and applications can make a world of difference. Ask for case studies, examples of past work, or references. This will give you a sense of their capabilities and reliability.

3. Make Precision A Priority

Precision is everything in CNC drilling. A small error can lead to costly mistakes or compromised product quality. Look for a service that uses advanced equipment and has strict quality control measures in place. Having certifications or other quality management standards can be a good sign that a company takes precision seriously.

4. Assess Technology And Equipment

CNC technology is constantly evolving, and newer machines often mean better results. Ask about the type of equipment the service uses. Do they have multi-axis machines? Are their tools capable of handling your material and design requirements? Services with up-to-date technology are more likely to deliver precise and efficient results.

5. Look Into Turnaround Times

Deadlines are critical. Whether you’re working on a tight schedule or planning ahead, you need a CNC drilling service that can deliver on time. Ask about their average lead times and whether they can handle rush orders if necessary. Reliable services will be upfront about their capabilities and timelines.

6. Do Cost Vs. Value Comparison

Price is always a factor, but it shouldn’t be the only one. The cheapest option might cut corners, while the most expensive service isn’t always the best. Look for a provider that offers a good balance of cost and quality. Get detailed quotes from several companies and compare what’s included. Sometimes, paying a little more upfront can save you headaches and money in the long run.

7. Ask About Additional Services

Some CNC drilling services offer more than just drilling. They might provide design assistance, prototyping, or post-processing services like deburring and finishing. Having these options available can simplify your workflow and ensure consistency across all stages of production.

8. Verify Material Capabilities

Not all CNC services are equipped to handle every material. Make sure the provider you choose has experience working with the material you’ve specified. Whether it’s a hard metal, a lightweight composite, or a delicate plastic, their expertise with your material is crucial.

9. Go Through Their Reviews

Online reviews and testimonials can offer valuable insights. Look for feedback from clients with similar needs to yours. While no company has a perfect record, a pattern of positive reviews is a good indicator of reliability and quality. Be cautious of services with consistent complaints about the same issues, such as missed deadlines or poor precision.

10. Pay Them A Visit

If the CNC drilling service is local, visiting their facility can be a game-changer. You’ll get a firsthand look at their equipment, processes, and overall professionalism. A tour can also give you confidence in their capabilities and help you build a stronger working relationship.

11. Make Sure They Can Accommodate Your Flexibility And Scalability Needs

Your needs might change over time. Whether you’re scaling up production or experimenting with new designs, it’s important to choose a CNC service that can adapt. Ask about their capacity for larger orders or custom adjustments. A flexible provider will be able to grow with your business.

12. Obtain A Sample Or Ask For A Trial

Before committing to a long-term contract, consider requesting a sample or trial run. This lets you assess the quality of their work firsthand. It’s a low-risk way to ensure they’re the right fit for your project.

13. Negotiate Project Contract Terms

Once you’ve chosen a provider, make sure everything is clearly outlined in your agreement. Discuss terms like payment schedules, lead times, and quality guarantees. A solid contract protects both you and the service provider and ensures everyone is on the same page.

Final Words

Picking the right CNC drilling service doesn’t have to be daunting. By defining your needs, researching thoroughly, prioritizing quality, and so on, you can find a provider that meets your expectations and delivers excellent results. With the right CNC drilling service by your side, you can bring your projects to life with precision, efficiency, and confidence.