Discrete manufacturing stands as a cornerstone in the intricate tapestry of industrial processes, playing a pivotal role in shaping the modern process manufacturing landscape. In this comprehensive exploration, we delve into the intricacies of discrete manufacturing, its core principles, technological advancements, and its profound impact on various industries.

Definition:

At its essence, discrete manufacturing refers to the production of distinct, individual units or items that can be easily identified and counted. This method contrasts with continuous manufacturing, where goods are produced in a constant, uninterrupted flow, such as in industries like chemicals, oil, and gas. Manufacturing, on the other hand, caters to the production of separate items with unique characteristics.

Key Characteristics :

Distinct Units: In manufacturing, products are created as separate entities with specific, identifiable characteristics. Each unit is distinguishable from the others, allowing for individual inspection and quality control.

Production Bill of Materials (BOM): It relies on a detailed production bill of materials, specifying the components, subassemblies, and processes required to assemble the final product. This granular breakdown aids in efficient planning and execution.

Customization: Discrete manufacturing is well-suited for industries where customization is crucial. Products can be tailored to meet specific customer requirements without significant alterations to the production process.

Batch Production: While each unit is unique, manufacturing often involves the creation of products in batches. This approach allows for efficient utilization of resources and streamlines the production process.

Technological Advancements:

The advent of Industry 4.0 and the integration of cutting-edge technologies have ushered in a new era for manufacturing. Several technological trends are reshaping the landscape:

Internet of Things (IoT): IoT plays a pivotal role in discrete manufacturing by connecting machines and devices on the production floor. Real-time data collection facilitates better decision-making, predictive maintenance, and enhanced overall efficiency.

Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms analyze vast datasets, offering insights into production patterns, quality control, and predictive maintenance. This data-driven approach enhances precision and reduces downtime.

Robotics and Automation: Automated systems and robotics streamline manufacturing processes, enhancing efficiency, reducing errors, and optimizing resource utilization. Collaborative robots, or cobots, work alongside human operators, augmenting productivity.

Digital Twin Technology: Digital twin technology creates virtual replicas of physical systems, enabling manufacturers to simulate and optimize processes before implementation. This minimizes risks and improves overall production outcomes.

Impact Across Industries:

Discrete manufacturing spans a diverse array of industries, each benefiting from its tailored approach:

Automotive Industry: It is foundational to automotive production, where each vehicle is assembled with distinct parts. Automation and robotics play a crucial role in ensuring precision and efficiency.

Electronics: The electronics industry relies heavily on manufacturing for the production of individual components such as microchips and circuit boards. Rapid advancements in technology necessitate flexibility and customization, making manufacturing ideal.

Consumer Goods: From appliances to personal electronics, manufacturing allows for the efficient production of consumer goods. Customization options cater to diverse consumer preferences.

Aerospace: In aerospace, where each component is critical and often custom-designed, manufacturing ensures precision and adherence to strict quality standards. Advanced materials and intricate components require a detailed and flexible approach.

Challenges in Discrete Manufacturing:

While discrete manufacturing brings forth numerous advantages, it is not without its challenges:

Complexity: The diversity of products and constant demand for customization can introduce complexity into the production process, requiring sophisticated planning and execution.

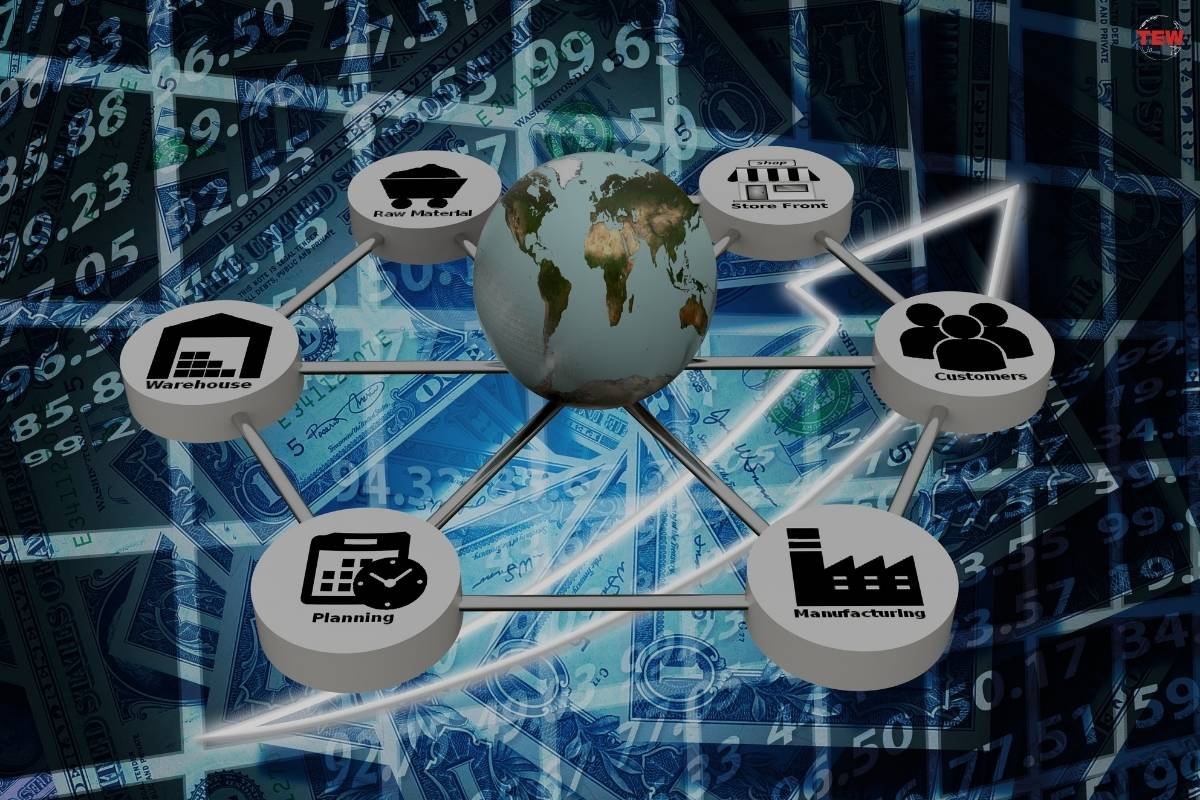

Supply Chain Management: Efficient supply chain management is crucial in manufacturing, as delays or disruptions can impact the timely production of individual units.

Technology Integration: Implementing and integrating advanced technologies like IoT and AI requires significant investment and expertise. Companies need to navigate this technological shift with careful planning and consideration.

Strategies for Success in Discrete Manufacturing:

To navigate the complexities of manufacturing successfully, industry leaders adopt several key strategies:

Agile Manufacturing: The ability to respond swiftly to changing customer demands and market trends is crucial. Agile manufacturing principles, including flexible production processes and quick adaptation to design changes, enable companies to stay ahead in the dynamic landscape.

Integrated Supply Chain: Seamless integration of the supply chain is imperative for efficient discrete manufacturing. Collaborative efforts with suppliers, distributors, and other stakeholders contribute to a well-coordinated and responsive supply chain, reducing lead times and minimizing disruptions.

Advanced Planning and Scheduling (APS): Utilizing advanced planning and scheduling software optimizes production processes by considering various factors such as machine availability, workforce scheduling, and material requirements. This enhances overall production efficiency.

Quality Management Systems: Maintaining high-quality standards is non-negotiable in manufacturing. Implementing robust quality management systems ensures that each produced unit meets stringent quality criteria, reducing defects and enhancing customer satisfaction.

Human-Machine Collaboration: While automation and robotics play a crucial role, fostering a collaborative environment between human operators and machines is equally important. Training and upskilling the workforce to operate alongside automated systems contribute to a harmonious and efficient manufacturing process.

Future Trends:

Looking ahead, several trends are poised to shape the future of discrete manufacturing:

Digital Thread: The concept of a digital thread involves creating a seamless flow of data across the entire product lifecycle, from design and production to maintenance and disposal. This interconnected digital framework enhances visibility, traceability, and decision-making throughout the product’s life.

Additive Manufacturing: Additive manufacturing, or 3D printing, is gaining prominence in manufacturing. This technology allows for the production of complex and customized components with reduced material waste, offering new possibilities for design and production.

Smart Factories: The evolution of smart factories involves the integration of smart technologies, IoT devices, and real-time data analytics. This interconnected ecosystem optimizes production, reduces downtime, and enhances overall operational efficiency.

Predictive Maintenance: Leveraging predictive analytics and machine learning, manufacturers can predict when equipment is likely to fail and schedule maintenance proactively. This minimizes unplanned downtime, improves asset reliability, and extends equipment lifespan.

Circular Economy Practices: Embracing circular economy principles involves designing products for reuse, remanufacturing, and recycling. Discrete manufacturers are increasingly exploring sustainable practices to reduce environmental impact and create closed-loop systems.

Conclusion:

In the dynamic landscape of modern manufacturing, it stands as a cornerstone, driving innovation, customization, and efficiency. As technological advancements continue to shape the industry, the future of manufacturing holds the promise of increased automation, improved connectivity, and unparalleled flexibility. This comprehensive exploration sheds light on the foundational principles, technological trends, and diverse applications that define the realm of discrete manufacturing.