When choosing motors for industrial equipment—whether it is heavy-duty machinery, production lines, automated handling systems, or logistics robots—buyers often encounter the same question: should they use a BLDC motor with a gearbox, or a direct-drive BLDC motor such as an outrunner or inrunner?

To non-engineers, this choice can appear highly technical, but the real consideration is much more practical. It is not about which motor is universally “better,” but which one is more appropriate for the specific application. In industrial environments, the right decision depends on factors such as load demands, required speed, reliability expectations, available installation space, and long-term operating cost.

Understanding these needs is what helps engineers and buyers decide between a geared BLDC system and a direct-drive BLDC system. The following sections explain their differences and why each may serve certain industrial scenarios more effectively.

What Does “BLDC” Mean?

Both motor types are based on the Brushless DC (BLDC) motor. Unlike traditional brushed motors, a BLDC motor uses electronic commutation rather than mechanical brushes and a commutator. This results in reduced friction, less wear, longer lifespan, higher efficiency, and smoother operation. BLDC motors also offer a high power-to-weight ratio and are widely used in industrial environments where stable, efficient, and low-maintenance operation is required.

Geared BLDC vs Direct-Drive BLDC (Outrunner / Inrunner)

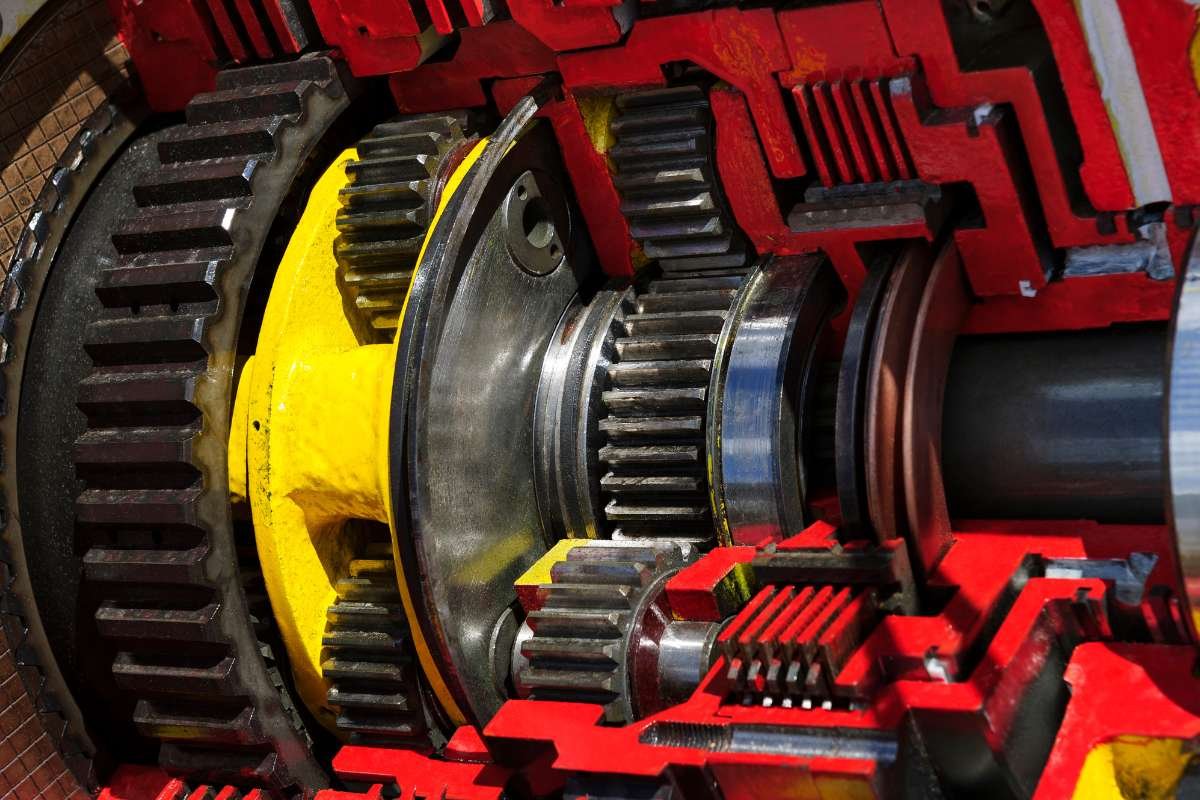

A geared BLDC motor combines a BLDC motor with a gearbox. The gearbox reduces output speed while multiplying torque, allowing even a relatively small motor to deliver significant load-handling capability.

A direct-drive BLDC motor connects the rotor directly to the load without mechanical gearing. Outrunner and inrunner BLDC motors both fall into this category. Industry application data shows that in most high-torque industrial environments, geared BLDC motors remain the preferred solution due to their stability and reliable low-speed performance. For example, an analysis of project cases from industrial drive supplier Brushless Inc. indicates that more than 70% of the heavy material-handling systems they support utilize geared BLDC configurations.

Outrunner vs Inrunner (Technical Supplement)

Outrunner BLDC motors use an external rotor and generally offer higher torque at lower speeds, while inrunner motors use an internal rotor and typically deliver higher rotational speeds with lower torque.

A Clear Comparison: Geared vs Direct-Drive BLDC Motors

| Feature | Geared BLDC | Direct-Drive BLDC (Inrunner/Outrunner) |

| Low-speed torque capability | Very high | Low to moderate (depends on motor torque constant) |

| Maximum speed capability | Lower | Very high |

| System complexity | Higher (includes gearbox) | Lower |

| Maintenance requirement | Moderate (lubrication, gear wear checks) | Low |

| Mechanical efficiency | 70%–95% (gear efficiency dependent) | Nearly 100% (no mechanical reduction losses) |

| Backlash | Present, affects precision | None |

| Cost range | Higher | Lower to moderate |

| Typical applications | High load, low speed, high torque | High speed, light to medium load, fast response |

This table helps illustrate that neither option is “better.” Instead, each serves a different category of industrial demand. Although initial costs differ, buyers should also consider long-term ownership costs: direct-drive motors typically reduce maintenance expenses, while geared BLDC systems often provide better performance value in high-torque applications.

Why Geared BLDC Motors Excel in High-Torque Industrial Scenarios?

For applications involving heavy loads, slow but powerful motion, or controlled operation under significant stress, geared BLDC motors often outperform direct-drive systems.

- High torque at low speed: Gear reduction allows the motor to deliver significantly amplified torque at low speeds, making it suitable for conveyors, lifting mechanisms, robotic joints, AGV/AMR drive wheels, and industrial actuators.

- High power density: Geared BLDC motors deliver substantial torque within compact form factors, addressing situations where available installation space is limited.

- Reliable and efficient operation: Although gearboxes introduce mechanical contact, a well-designed gear system provides stable performance, low noise, and good durability.

Understanding Backlash and Efficiency (What Buyers Should Know)

- Some gearboxes introduce slight “play” or backlash; this matters mostly for ultra-precise positioning.

- Gear efficiency ranges between 70–95%, depending on gear type and stages.

- Backlash affects precise positioning accuracy, though planetary or zero-backlash gearboxes can significantly reduce this effect.

- Gearbox efficiency also varies with lubrication and the number of gear stages; multi-stage gearboxes reduce speed further but increase torque.

These factors are normal characteristics of mechanical transmission systems and are not typically deal-breakers unless your equipment requires extremely precise micro-movement

When Direct-Drive BLDC Motors Are the More Cost-Effective and Practical Choice

Direct-drive motors shine in applications where speed, simplicity, and low mechanical maintenance matter more than raw torque. Examples include:

- High-speed spindles and rotary tools

- Blowers, fans, and centrifugal equipment

- Fast-moving conveyor belts

- Small robotic mechanisms

- Inspection and testing devices

Buyers often choose direct-drive BLDC motors because:

1. They achieve very high speeds effortlessly

Since there is no gearbox limiting the RPM, direct-drive motors can reach extremely high rotational speeds smoothly.

2. They reduce system complexity

Fewer mechanical parts mean fewer points of failure. This can significantly lower long-term maintenance costs.

3. They provide zero backlash

For precision scanning, camera systems, or small automated devices, this level of accuracy is valuable.

Different industries also tend to favor different solutions—for example, AGVs and lifting systems commonly adopt geared BLDC motors, while high-speed packaging, inspection tools, or airflow applications often rely on direct-drive designs.

How to Choose the Right Motor: Key Questions for Engineers and Decision-Makers

Choosing an undersized direct-drive motor for high-torque tasks can lead to overheating and reduced lifespan, while using a geared motor in a high-speed application may limit responsiveness. Selecting the wrong configuration often results in avoidable downtime and increased operational costs.

Selecting between a geared BLDC motor and a direct-drive BLDC motor ultimately comes down to understanding what your application demands. Instead of comparing technical specifications in isolation, focus on the following core questions that directly influence real-world performance, reliability, and cost.

1. How heavy is the load?

Heavy, torque-intensive loads are better handled by geared BLDC motors, which amplify torque through mechanical reduction.

For lighter loads that do not require torque multiplication, a direct-drive BLDC motor is often sufficient.

2. What speed does your system require?

If your application needs high RPM and rapid response, direct-drive motors are the natural fit.

If you need strong, controlled motion at low speeds, a geared motor provides the necessary output.

3. Are there space limitations?

When a compact machine must still deliver high torque, a geared BLDC motor makes more efficient use of limited space.

Direct-drive motors are usually smaller in overall system complexity but cannot provide the same torque density at low speeds.

4. What are your maintenance expectations?

Direct-drive motors contain fewer mechanical components and therefore typically require minimal maintenance.

Geared systems are also reliable but may require periodic lubrication and gear inspection, especially in continuous-duty environments.

5. What budget are you working with?

A gearbox increases both cost and mechanical complexity. However, if your application demands high torque or load-bearing stability, the performance benefits often justify the investment.

Direct-drive systems usually cost less upfront, but only when their performance fits the application.

By evaluating these questions together—load, speed, space, maintenance, and budget—you can confidently align your motor choice with the true needs of your equipment, rather than relying solely on technical data sheets or generalized assumptions. The right decision is always the one that best matches your specific operating conditions.

Conclusion

For equipment running below roughly 300 RPM or requiring steady torque above about 10–20 Nm, a geared BLDC motor is usually the most reliable choice. The gearbox provides the torque amplification and load stability needed for heavy-duty industrial tasks. This is why most torque-intensive automation systems continue to adopt geared BLDC motors, a category in which Brushless Inc. provides a wide range of worm-gear BLDC solutions across 50W to 2000W applications.

If your application prioritizes high speed, fast response, simpler mechanics, and minimal maintenance, a direct-drive BLDC motor—inrunner or outrunner—will be more efficient and cost-effective.

In short, choose geared BLDC for high torque and demanding loads; choose direct-drive BLDC for speed and simplicity. The right decision depends on the real operating requirements of your equipment.

Read Next: Leveraging Modern Drive Technologies To Boost Industrial Productivity