Hayato Isesaki (CEO of Spacewasp and CEO of NoMaDoS) is an architect and entrepreneur driven by a deep commitment to tackling both environmental and architectural challenges. He earned his graduate degree in Urban Architecture from Tohoku University, where he explored circular systems that connect natural ecosystems with the built environment. After working at a prominent architectural design firm, he established his own practice, NoMaDoS, in 2018. He went on to found Polyuse in 2019—Japan’s first construction 3D printing company—and later launched Spacewasp in 2022, a hard-tech startup focused on transforming plant waste into sustainable interior materials.

“I believe leadership isn’t about following a fixed structure, but about adapting systems to fit the challenge. Each project has unique goals, contexts, and stakeholders, so I design each organization—like NoMaDoS, Spacewasp, and Polyuse—with a leadership style tailored to its specific needs. This flexible, question-driven approach reflects my core philosophy: the system should serve the problem, not the other way around.” added Hayato Isesaki.

Decarbonizing Design

With firsthand experience of climate change’s effects, Hayato Isesaki combines technical knowledge and on-the-ground insight to create scalable, sustainable architectural solutions. At Spacewasp, he is developing fully automated systems that turn plant-based waste—materials typically destined for incineration—into eco-friendly architectural finishes and furniture. This innovative process supports decarbonization by ‘fixing CO₂ into spaces,’ helping to reduce atmospheric emissions.

- Earned a Master’s degree in Urban Architecture from Tohoku University, with a research focus on circular systems integrating nature and the built environment.

- Worked as a design architect at a leading architectural firm.

- 2018 – Founded the architectural practice NoMaDoS.

- 2019 – Co-founded Polyuse, Japan’s first construction 3D printing company.

- 2022 – Founded Spacewasp, a hard-tech startup transforming plant waste into sustainable interior materials.

NoMaDoS: Where Curiosity Builds the Future

NoMaDoS operates as an architectural creative collective, driven by the mission of “Endless Independent Research.” The collective views the world as a dynamic testing ground and architecture as an experimental tool, with the overarching vision to “expand cities, spaces, and lifestyles.” Their team, comprised of licensed architects, brand producers, marketers, writers, real estate professionals, and designers, reflects a diverse range of expertise. At the core of NoMaDoS’s work lies the conviction that continuous self-evolution is essential for generating new value. This philosophy permeates all aspects of their operations, influencing their core values, work methodologies, organizational structure, and business practices.

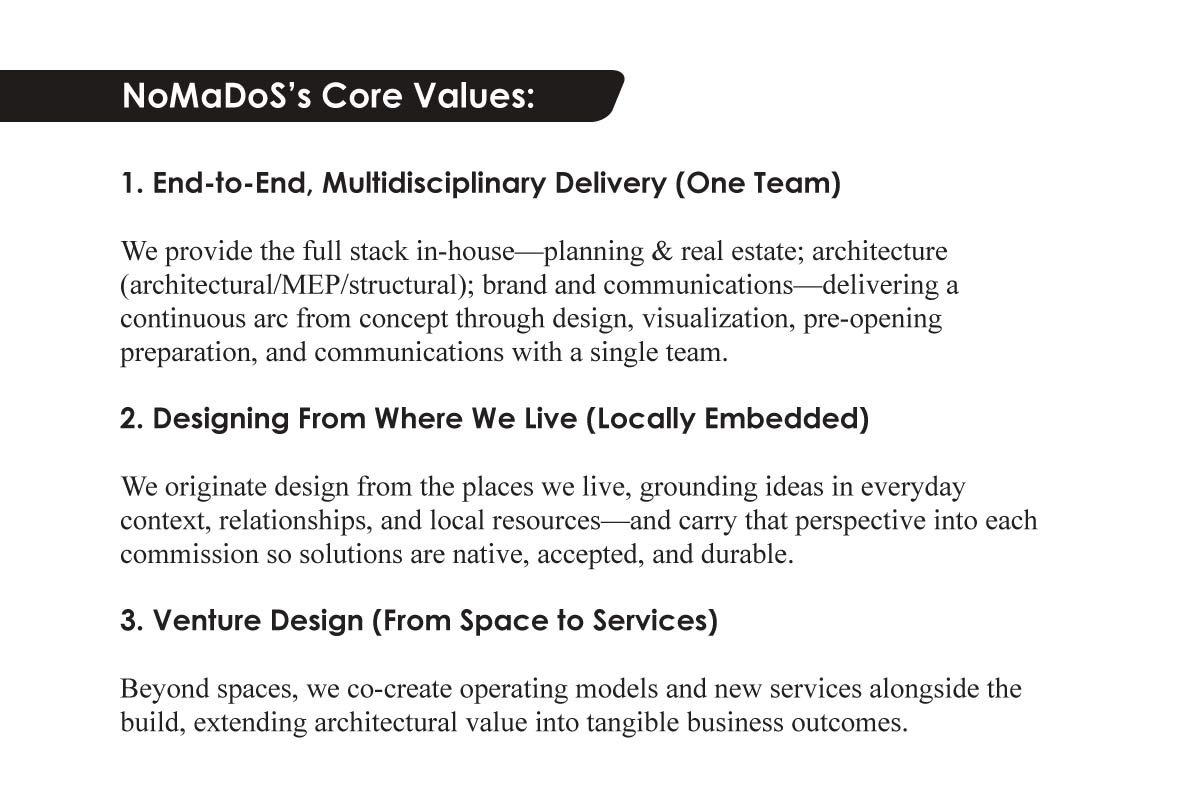

NoMaDoS’s Core Values:

1. End-to-End, Multidisciplinary Delivery (One Team)

We provide the full stack in-house—planning & real estate; architecture (architectural/MEP/structural); brand and communications—delivering a continuous arc from concept through design, visualization, pre-opening preparation, and communications with a single team.

2. Designing From Where We Live (Locally Embedded)

We originate design from the places we live, grounding ideas in everyday context, relationships, and local resources—and carry that perspective into each commission so solutions are native, accepted, and durable.

3. Venture Design (From Space to Services)

Beyond spaces, we co-create operating models and new services alongside the build, extending architectural value into tangible business outcomes.

Integrated Services for a Changing World

To effectively navigate the rapidly evolving economic, cultural, and market landscapes, NoMaDoS employs a compact, versatile organizational structure. Their proficiency encompasses a wide spectrum of disciplines, including architectural, equipment, and structural design, alongside planning, branding, marketing, creative direction, finance, and real estate. This comprehensive skill set enables NoMaDoS to deliver seamless, integrated, and adaptable end-to-end services.

The NoMaDoS Method

NoMaDoS operates on the principle that evolution in design begins by responding to the shifting questions society presents. Their process starts by identifying areas of tension or ambiguity within a project. From there, the team engages in internal dialogue, formulates hypotheses, and conducts small-scale experiments to explore possible directions.

With a flexible, project-based structure, NoMaDoS can rapidly reconfigure teams and adapt outputs, enabling them to respond to emerging themes in real time. This agility is central to their practice, allowing them not only to address complex societal issues but also to continually challenge and expand the definition of what architecture can be.

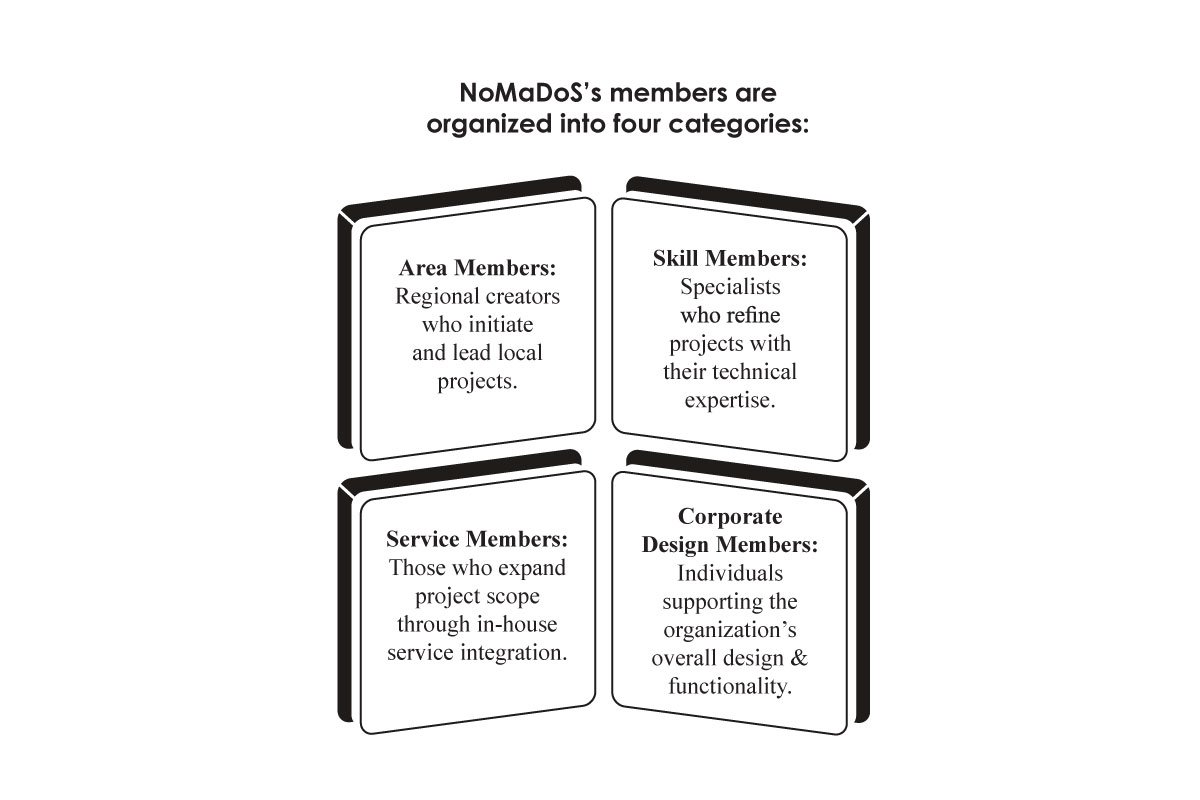

NoMaDoS’s members are organized into four categories:

- Area Members: Regional creators who initiate and lead local projects.

- Skill Members: Specialists who refine projects with their technical expertise.

- Service Members: Those who expand project scope through in-house service integration.

- Corporate Design Members: Individuals supporting the organization’s overall design and functionality.

The Dual Design Approach

NoMaDoS operates on the principle that diverse lifestyles and perspectives generate innovative value. They empower their members with the freedom to live and work from any location, within Japan and internationally, and to manage their work hours and methods autonomously. This autonomy accommodates varied schedules and personal priorities, including family and side projects. Within the architectural domain, members may pursue independent small-scale ventures while collaborating with NoMaDoS on larger projects. This flexibility cultivates well-being, mutual respect, and creative expression, all of which are vital to their mission.

NoMaDoS approaches business as a design subject, extending its creative process beyond traditional architecture. They employ two distinct design lenses:

- Solution Design: This approach involves collaborating with regional companies to develop projects tailored to the unique characteristics of each local context. NoMaDoS moves beyond conventional architectural services, providing branding, content creation, and spatial design that integrate both tangible and intangible elements to facilitate community transformation.

- Speculative Design: NoMaDoS utilizes this approach to engage with broader societal issues. They propose experimental, future-oriented ideas through provocative design, aiming to broaden the perceived role of architecture in society by exploring emerging challenges and opportunities.

From Sustainability to Speculation

NoMaDoS’s key projects showcase its diverse and innovative approach to architecture and design:

- slowz: A mapping application that focuses on the emotional and physical locations of sustainable initiatives and businesses throughout Japan.

- Shinsekai Architecture Map: A speculative media project that envisions near-future architecture through storytelling, character design, and spatial concepts.

- Dot-Pixel Real Estate (Morioka Dot-E Real Estate): A social media experiment that uses pixel art to rediscover and reinterpret local architecture and cultural identity.

- Architectural Anatomy of Subculture: A book that compares architectural depictions in anime and manga with real-world architectural history and technology, making complex ideas fun and accessible—while addressing labor shortages in the industry.

- archiripple: A matching platform that connects architecture-related businesses with architecture media, energizing the industry through mutual collaboration and visibility.

- Aluuru: An educational project that nurtures children’s creativity through a fun, architecture-themed role-playing game—cultivating the next generation of design talent.

- Spacewasp: Originating from NoMaDoS’s speculative design explorations, Spacewasp tackles construction industry challenges through plant-based interior manufacturing. Now an independent startup, it provides sustainable, automated interior solutions with global and space-oriented aspirations.

Spacewasp: Sustainable Interiors from Plant Waste

Vision: Spacewasp envisions a world where global environmental sustainability and human living spaces coexist harmoniously.

About Spacewasp: Spacewasp is a technology startup specializing in the transformation of plant waste into sustainable architectural interiors. Building on the principles of biophilic design, their system integrates circularity and automation to create eco-friendly spaces with unprecedented speed and efficiency.

Mission: Recognizing humanity’s inherent connection to nature, Spacewasp advances biophilic design by utilizing a closed-loop system and automated production to convert plant waste, a highly renewable resource, into next-generation interior materials. Their mission is to close the waste loop and integrate sustainable living into everyday environments. “In an era of escalating environmental challenges, we place sustainability at the heart of every space. By fusing innovation with environmental responsibility, we are paving the way to a more conscious lifestyle,” states CEO Hayato Isezaki.

Unique Features:

- Zero-Waste Interior Material Process: Spacewasp collects plant waste from various sources including agriculture, food processing, and forestry, and transforms it into high-performance plant-based resins. These resins are then used to manufacture boards, furniture, substrates, and upholstery fabrics. All products are recyclable and remanufacturable, enabling a fully closed-loop waste cycle.

- Dual-Cycle Automated Interior Manufacturing System: Their system operates through two interconnected cycles: the Plant Cycle, focused on material conversion, and the Interior Cycle, dedicated to the design, manufacture, and installation of interior spaces. This proprietary process is executed within a fully automated production facility.

- 3D Scanning × AI × Automated Manufacturing: Spacewasp captures accurate room dimensions through 3D scanning of interior spaces, then uses AI to automatically generate customizable designs. It provides instant cost estimates and layout plans, and utilizes 3D printers and panel fabrication machines for automated production. This system minimizes environmental impact while achieving up to 90% reduction in construction time and 30% cost savings compared to traditional methods.

- Spacewasp captures accurate room dimensions through 3D scanning of interior spaces, then uses AI to automatically generate customizable designs. It provides instant cost estimates and layout plans, and utilizes 3D printers and panel fabrication machines for automated production. This system minimizes environmental impact while achieving up to 90% reduction in construction time and 30% cost savings compared to traditional methods.

- Compliance with Global Environmental and Building Regulations: Spacewasp’s system digitally integrates local building codes and environmental regulations, enabling flexible and responsible production worldwide. It also centralizes supply chain management and visualizes carbon impact, ensuring both sustainability and scalability.

Social Value & Brand Positioning

Spacewasp is setting a new standard in interior architecture through sustainability, automation, and circularity—delivering lasting impact across the environment, society, and culture.

Environmental Impact

1. Carbon-Negative Materials

By transforming plant waste into building components, Spacewasp sequesters CO₂ within interior spaces—contributing to a decarbonized society.

2. Regenerative Design

Materials are designed for collection and remanufacturing after use—creating spaces that improve the environment over time.

Manufacturing Innovation

1. Full Vertical Integration

End-to-end in-house control from raw material development to on-site installation ensures high quality and efficiency.

2. Smart Interior Factories

AI × automation enables zero-waste, on-demand production—supporting high-mix, small-batch, short-lead projects.

Cultural & Emotional Value

1. Spaces with a Story

“This wall was made from vegetables grown in ○○.”

“This table came from ○○ company’s food by-products.”

Each space tells a story through material origin.

2. Co-Creation with Creatives

Collaborations with architects, designers, and artists amplify spatial expression and strengthen brand identity.

Social & Regional Contribution

1. Local Economic Circulation

By working with agriculture, forestry, food, tourism, logistics, and more, Spacewasp builds local-to-local material supply chains.

2. Empathetic Spatial Design

Creating spaces that are comfortable and accessible for children, seniors, and people with disabilities—spaces that consider everyone.

3. Subscription-Based Space Model

Interior materials and furniture can be updated periodically, promoting a circular and ever-evolving lifestyle.

The Spacewasp Approach to Systems Innovation

Spacewasp’s evolution is shaped by a dynamic interplay between ground-level insights and a forward-thinking environmental vision. The company gathers granular user feedback related to cost, delivery, and performance constraints while simultaneously working backwards from a long-term vision rooted in decarbonization, circularity, and automation.

Weekly cross-functional reviews serve as a bridge between theory and practice, enabling the immediate integration of real-world input into prototype development. This agile feedback loop ensures that on-site learnings are rapidly tested, refined, and scaled.

At the heart of Spacewasp’s innovation cycle is its ability to align hands-on experimentation with strategic execution—creating solutions that are not only visionary but also grounded in practical, scalable outcomes.

Polyuse: Where Construction Meets Innovation

Vision- Polyuse envisions a future where humans and technology coexist seamlessly, made possible through the adoption of 3D printing technology for construction use.

Mission- To modernize and transform the Coexistence of people and technology

Background & Industry Challenges

Japan’s construction sector is facing a critical labor shortage, with an anticipated shortfall of 470,000 to 930,000 workers by 2025. Nearly 43% of the workforce is over the age of 55, underscoring a rapidly aging labor pool.

Simultaneously, much of Japan’s infrastructure is aging and in urgent need of renewal—especially in anticipation of increased strain by 2040. The Noto Peninsula Earthquake on January 1, 2024, which tragically claimed over 500 lives, further emphasized the pressing need to modernize and reinforce national infrastructure.

To meet these challenges, the industry must find ways to construct concrete structures more quickly, efficiently, and with fewer human resources.

Polyuse’s development process is fundamentally driven by on-site trials. The company’s evolution is rooted in a continuous cycle of field validation, thorough failure analysis, and subsequent system upgrades. By maintaining constant dialogue with municipalities and contractors, Polyuse ensures the relevance and adaptability of its solutions. Improvements are implemented iteratively, always with a clear objective: to deliver dependable, future-ready infrastructure through the application of digital construction methodologies.

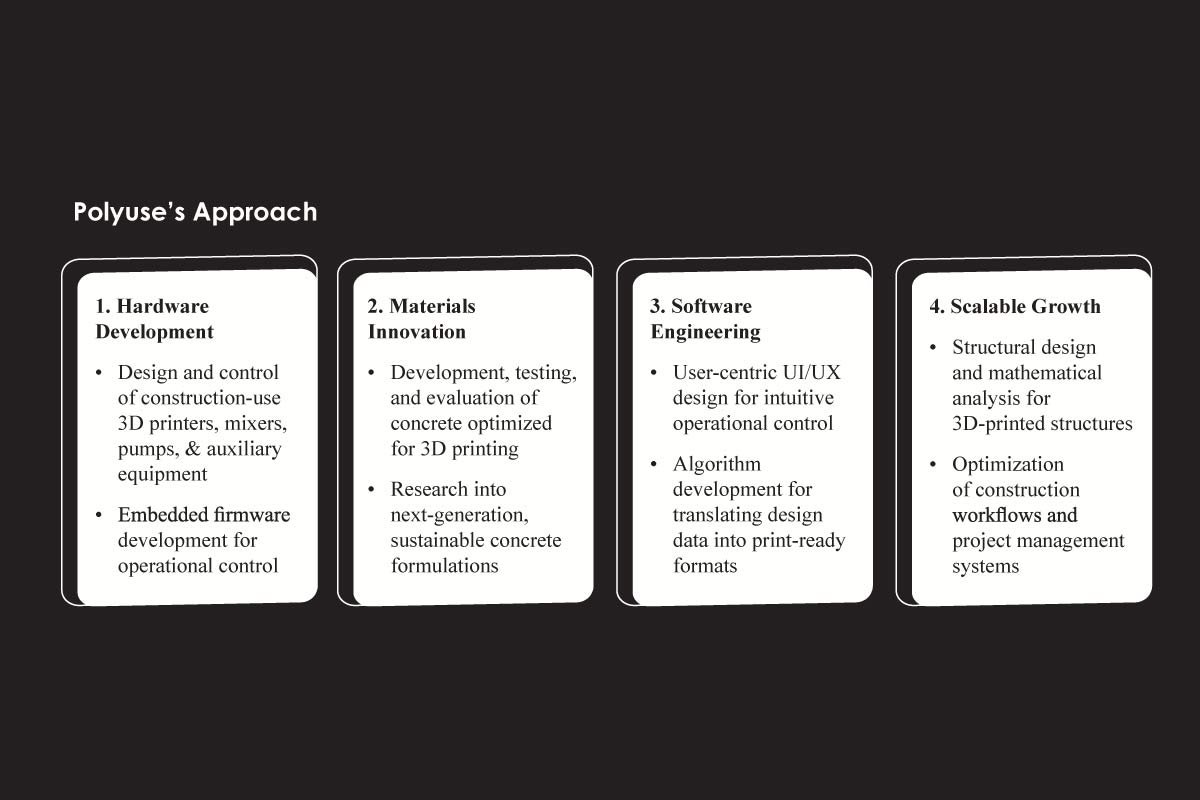

Polyuse’s Approach

1. Hardware Development

- Design and control of construction-use 3D printers, mixers, pumps, and auxiliary equipment

- Embedded firmware development for operational control

2. Materials Innovation

- Development, testing, and evaluation of concrete optimized for 3D printing

- Research into next-generation, sustainable concrete formulations

3. Software Engineering

- User-centric UI/UX design for intuitive operational control

- Algorithm development for translating design data into print-ready formats

4. Scalable Growth

- Structural design and mathematical analysis for 3D-printed structures

- Optimization of construction workflows and project management systems