5G is Transforming the Manufacturing Industry

5G networks that transform transportation, communication, and entertainment may still be years away. But this 5G technology is already making a difference in the manufacturing sector. The next-generation 5G networks are making communication between servers and devices much faster as it is 100 times faster than the 4G network.

In addition, the combination of practicality, speed, and potential cost savings are some of the factors that are encouraging factory operators to test with 5G. The results have been positive, proposing that the technology should be widely used in factories prior to being used in smartphones and other consumer products.

Ways in Which 5G is Transforming the Manufacturing Industry

Just imagine a future where smart robots are employed to assemble products from multiple manufacturing lines and are also physically reconfiguring themselves on the factory site. In addition, the security drones are handling tedious tasks ranging from checking for intruders to validating employee parking. The factory inspections are performed remotely and the autonomous vehicles are transporting parts all across the nation and not only between buildings.

These were impossible just a few years ago, where all these dreams were held in reserve for the realms of science fiction. However, the arrival of 5G connectivity coupled with advances in cloud computing and artificial intelligence (AI) have made these dreams increasingly attainable for manufacturing organizations.

Today, 5G is appearing to be a promising opportunity to strengthen both digitization and connectivity within the four walls of factories and beyond them at every stage along the entire value chain. Listed below are four ways that show strong potential for improving factory productivity:

1. Augmented Reality (AR)

Factory workers are not unfamiliar to perform complex control and maintenance tasks, frequently guided by standard operating procedures (SOPs) in videos, paper manuals, videos, or in some cases even AR. However, instructions streamed over 4G networks can be undependable owing to bandwidth constraints, and miss the mark to deliver the required levels of quality devoid of stuttering. This is the way can say 5G is Transforming the Manufacturing Industry.

On the other hand, 5G promises shutter-free AR that can guide people at every stage and also promises the streaming of high-quality instructions on the shop floor. This will enable shop-floor workers to carry out advanced tasks without waiting for incurring costly machines or specialist engineers. The work instructions and the best knowledge can, therefore, be shared with all then workers when they need them most. This will help in building worker skills more effectively, safely, and quickly than ever before.

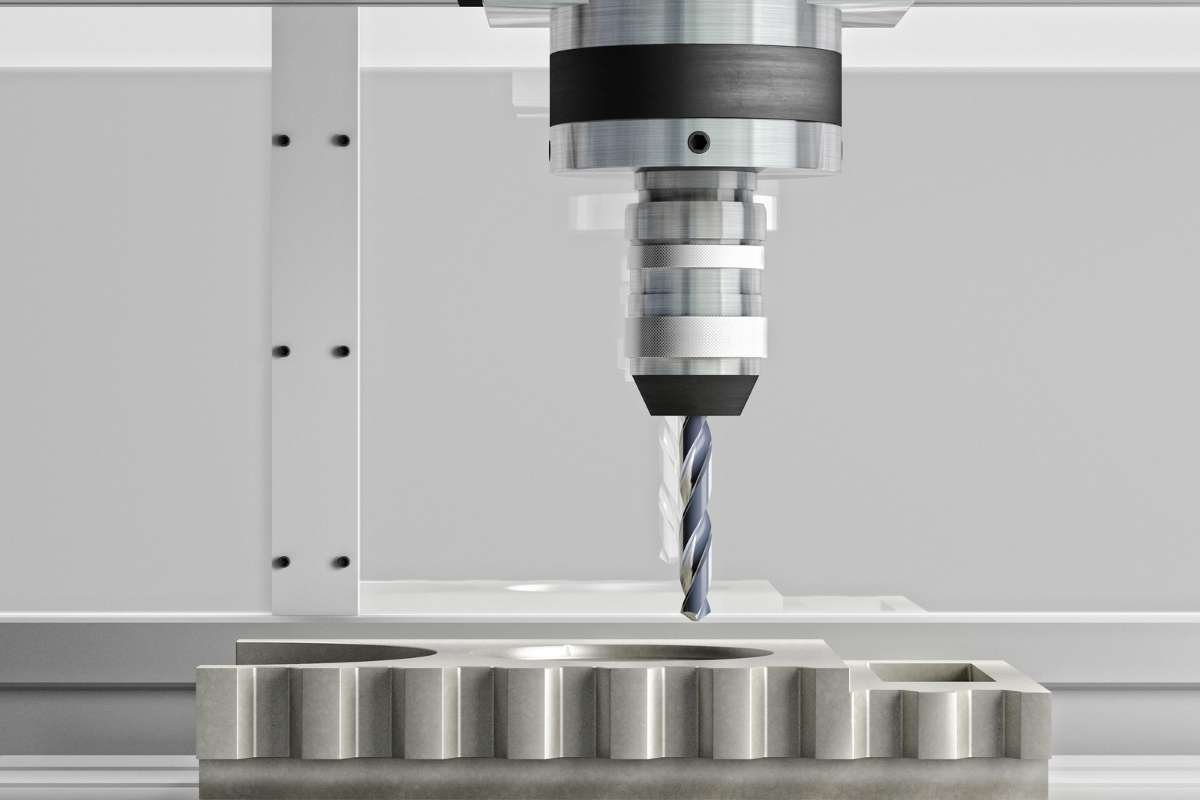

2. Cloud Control of Machines

Factory automation has relied on PLCs or programmable logic controllers for decades. These PLCs were physically installed on the machines they controlled and then wired into computer networks to guarantee reliable and precise control under extreme conditions. The PLC could be controlled wirelessly in real-time if the 5G consistently meets its performance promises at a fraction of the existing cost. Cloud Control is the example that 5G is Transforming the Manufacturing Industry.

3. Perceptive AI Eyes on the Factory Sight

In modern factories, cameras are already common to manage security and monitor processes. However, their use often requires the worker to monitor video feeds as it is limited to focused applications. 5G will allow the streaming of live video analytics and data in real-time to the cloud. For instance, a security camera could identify if there is an imminent danger or threat, see a disturbance, and also alert a worker or dispatch a drone to investigate. The same security camera could alternatively provide a more effective mechanism to monitor process deviations and measure cycle times. In this way, 5G is Transforming the Manufacturing Industry.

4. Shop Floor IoT

The addition of sensors to numerous machines means that the factories are creating more data than ever before. Wi-Fi networks can rapidly get congested as the transmission through wired networks is expensive to scale. 5G can support high connection solidity with tens of thousands of endpoints, thus truly empowering the use of industrial data at scale. Shop Floor IoT is the way 5G is Transforming the Manufacturing Industry.

Although, these technologies are all still at an initial stage of testing, the pilots embarked on to date are encouraging. One of the most intriguing effects of 5G technology would be on humans who work alongside it. Far from creating a world of human-free factories, lights-out, industrial 5G appears more likely to allow individuals to move away from tasks that have formerly been considered dangerous, dull, and dirty. Instead, the focus of people will shift towards capturing the value made possible that 4G could not seamlessly and reliably support at scale.

For recent and latest updates regarding business news, industry trends, etc. Please subscribe Newsletter from “The Enterprise World” at “Subscribe”