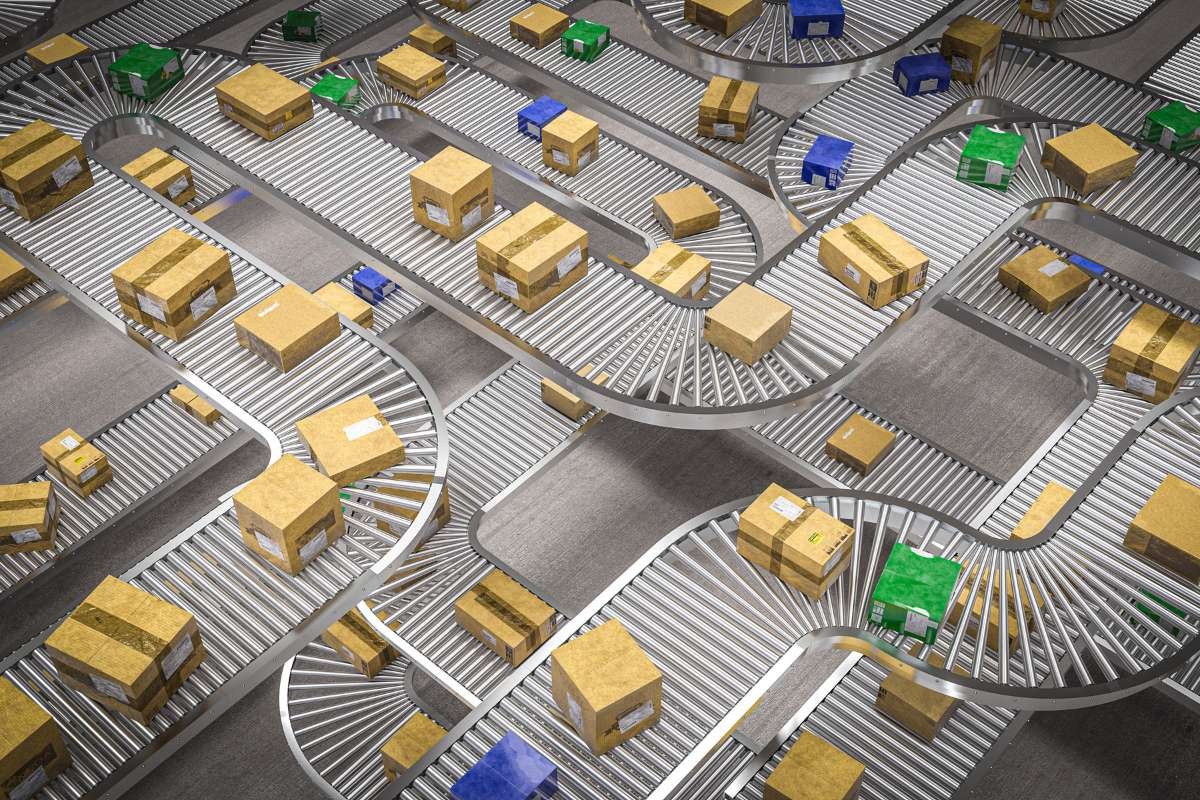

The movement of materials is the backbone of modern industry. Whether it is raw ore, mechanical components, or a packaged meal, the process has to be fast and efficient. That’s where the conveyor system comes in.

Conveyor belts do more than just move things from one place to another. They are central to improving efficiency, safety, and automating factories and warehouses. They are found everywhere in every industry. But not all types of conveyors and their uses are the same. The right choice depends entirely on what you’re moving.

Find out the 3 benefits of using a conveyor

Before we read about the types of conveyors and their uses, let’s talk about their benefits.

Conveyor systems have a wide range of applications and functions. Let us take a look at three reasons why they are so important in almost every automation system.

1. Cuts down on manual waste

Automating tasks like moving extremely heavy objects is essential to eliminating manual waste. It also prevents employee injuries. Attempting these tasks manually adds no value and increases safety risks.

An automated conveyor solution significantly speeds up production. They also boost plant productivity. And allow employees to focus on critical, value-added business development tasks.

2. Allows for adaptability

Flexibility is critical for achieving lean operations. Think again if you believe conveyors are immobile and inflexible. Modular conveyors aid in achieving the required flexibility for various operations. They can also be easily set up in the field.

Modular conveyors allow you to tailor the conveyor system to your specific needs. It is advisable to invest in one that can be moved to better serve your needs.

3. Improve quality control

Automated systems integrating high-speed cameras significantly boost quality control. It detects and eliminates faulty products or scrap on fast-moving conveyors. This camera data allows other systems to remove items. It also helps in detecting critical issues like unwanted metal or faulty parts.

Conveyor solutions also efficiently orient products for the next assembly stage. It basically helps in eliminating repositioning waste. This increases throughput and ensures higher customer satisfaction with high-quality output.

What are the 13 Different Types of Conveyors and Their Uses?

Now, let’s talk about the thing that brought you here: Types of conveyors and their uses. There are 13 types of conveyors used in various industries.

Let’s take a look at each of them:

1. Spiral Conveyors

A Spiral conveyor is a vertical system using a continuous belt or chain in a compact helix. It is used to gently transport products up or down between different levels. These types of conveyors and their uses in minimizing floor space are important. They reduce floor space while maintaining a steady, high-throughput flow.

- Applications: Absolutely essential for space-saving vertical transport in high-density factories and warehouses.

2. Belt Conveyors

These are versatile types of conveyors, and their uses involve transporting material horizontally. They are continuous loops of material stretched between two or more rotating pulleys. They are often found in mining, logistics, and packaging.

- Applications: They are workhorses for bulk handling (like coal or grain), mining, and automotive assembly (CNC machinery).

3. Roller Conveyors

Roller conveyors consist of parallel rollers mounted within a frame. It allows products with flat bottoms, like boxes or pallets, to be moved. They can be unpowered (relying on gravity) or powered by motors. They are common types of conveyors, and their uses in warehousing are very important.

- Applications: Ideal for moving flat-bottomed items like boxes, totes, and pallets. Used in warehousing, packaging, and sorting facilities.

4. Magnetic Conveyors

Magnetic conveyors use powerful electromagnets to move items made of ferrous metal. These systems are effective for transporting small parts, screws, or metal stamping scrap. Their enclosed design prevents debris from contaminating the workspace.

- Applications: Moving small metal parts, removing machining scrap (chips and swarf).

5. Chute Conveyors

Chute conveyors are the simplest types of conveyors. They rely entirely on gravity to move items. They consist of a smooth, inclined surface, like a slide. This design allows products or scrap materials to move downward efficiently. These systems are energy-free and virtually maintenance-free. This makes them incredibly simple and cost-effective for downward transport.

- Applications: Simple scrap handling, rapid downward movement in mail and parcel sorting. Also used in transporting boxes between mezzanines.

6. Pneumatic/Vacuum Conveyors

Pneumatic conveyors are types of conveyors, and their uses include moving materials through tubes. They use air pressure or vacuum instead of mechanical components. This system is highly effective for moving fine, powdered, or granular materials. It is used in a completely sealed, dust-free environment.

- Applications: Handling fine materials in pharmaceuticals, chemical, and food industries. Also used as dust collection systems.

7. Spiral Conveyors

The spiral conveyor is a specialized system designed for continuous, high-throughput vertical movement. This type of conveyor uses a helical track with an incline. It allows it to smoothly lift or lower products between different floors in a facility. This design is absolutely essential for space-saving vertical transport in dense warehouses.

- Applications: Absolutely essential for space-saving vertical transport in high-density factories and warehouses.

8. Bucket Conveyors (Elevators)

These types of conveyors and their uses in agriculture, mining, and construction industries are central. It features a series of buckets attached to a belt or chain to vertically lift bulk materials. It is used to lift materials like grains, cement, or sand. They are commonly deployed in industries with high-capacity movement of loose goods.

- Applications: Primarily used for efficient vertical lifting of granular materials. It is used to lift grains, sand, cement, and mining materials.

9. Overhead Conveyors

Overhead conveyors are suspended systems that move materials through production or assembly lines. They use trolleys and carriers hanging from an overhead track to move items. This design is highly advantageous because it saves valuable floor space. It keeps the work area clear and optimizes the manufacturing layout.

- Applications: Standard in the automotive, aerospace, and garment industries. Used for moving large components or clothes hangers.

10. Screw Conveyors (Auger Conveyors)

A screw conveyor consists of a rotating helical screw blade inside a trough or tube. It specialized in moving bulk materials like powders and granules. As the screw turns, it pushes the material along the length of the trough. This provides a sealed and controlled method of transport.

- Applications: Used in food processing, agriculture, chemical plants, and wastewater treatment.

11. Modular Plastic Belt Conveyors

Modular plastic belt conveyors are unique types of conveyors and their uses in clean industries are very important. They play a major role in the food, beverage, and pharmaceutical industries. They’re constructed from interlocking plastic segments, not a single continuous belt. This design creates a highly flexible surface that is easy to modify.

- Applications: Necessary in highly regulated and clean industries. It is used in food processing, pharmaceuticals, and bottling.

12. Flexible Conveyors

These types of conveyors and their uses are good for docks and setting up warehouses. As the name suggests, they can be easily stretched, retracted, and curved to adapt to the floor plans. These portable systems are ideal for temporary setups. They are mostly used in moving packages at shipping docks.

- Applications: Moving packages at shipping docks, temporary setups in warehouses. It can be used in any scenario where the layout frequently changes.

13. Slat Conveyors

Slat conveyors employ discrete, rigid slats attached to chains to move materials. It offers a highly stable and flat surface. This design makes them ideal for transporting heavy, bulky, or irregularly shaped items. They are frequently used in demanding applications. This includes automotive assembly lines and heavy construction or recycling processes.

- Applications: Used when the product is large, heavy, or has an irregular shape. Used in automotive assembly, construction, and heavy recycling.

Conclusion:

The conveyor types are specialized systems for every material-handling challenge. Choosing the right conveyor is a critical decision that depends on several factors. You must consider the material being moved, the load capacity, the speed, and the plant layout. Understanding the types of conveyors and their uses is fundamental to this decision.

Modern conveyor systems are automated components for increasing productivity. They are pivotal in reducing manual intervention in industrial environments and function as the logistical backbone of the modern supply chain. They ensure that materials are precisely where they need to be, exactly when they are needed. Knowing these types of conveyors and their uses is key to maintaining efficiency.

FAQs

1. What is the main purpose of conveyor systems in modern industry?

Conveyors are essential for automating material movement, maximizing productivity, and significantly boosting safety. It reduces the need for manual handling of heavy or numerous items. And most importantly, makes processes fast and efficient.

2. Which types of conveyor and their uses are best for handling bulk?

Belt Conveyors are typically the best choice for bulk handling. It is due to their versatility and cost-effectiveness in transporting large quantities. They are perfect for carrying materials like ore, coal, or grain over long distances.

3. How do conveyor systems improve quality control?

By integrating with high-speed cameras and automated systems. Conveyors allow for the rapid detection of faulty products. This ensures high-quality output and precise product orientation for subsequent assembly.