In today’s competitive industrial landscape, improving production efficiency while reducing energy consumption is no longer an option but a necessity. Among the most advanced solutions available, catalytic gas radiant panels stand out for their ability to deliver consistent heat, lower operational costs, and enhance product quality. These systems, also referred to as industrial catalytic heaters, have become a benchmark for innovation in sectors ranging from metal finishing to plastics, coatings, and wood processing. Companies like Infragas have contributed significantly to this technological evolution, designing catalytic heating systems that combine high performance with sustainability.

How Catalytic Gas Radiant Panels Work?

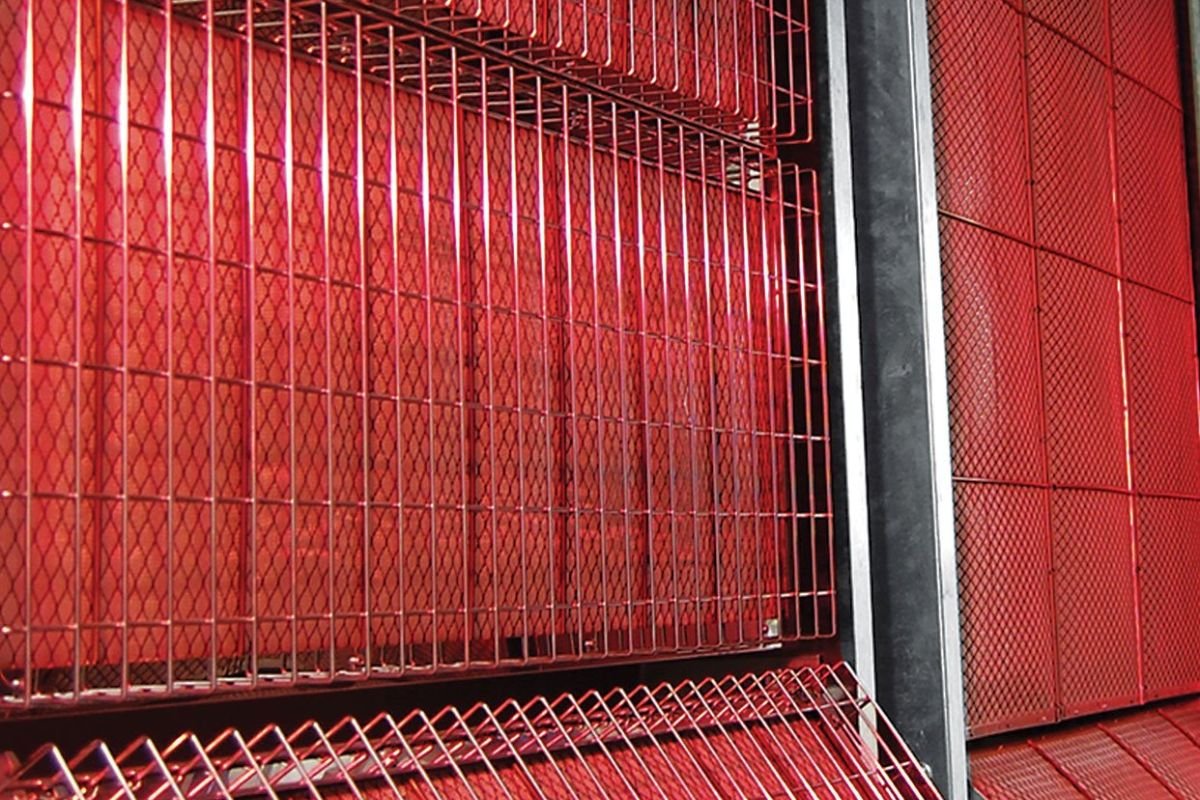

Catalytic gas radiant panels use a controlled chemical reaction between gas (usually propane or natural gas) and oxygen on a catalytic surface to generate infrared radiation without flame. This process produces uniform heat distribution over large surfaces, allowing precise temperature control and faster response times.

Unlike conventional combustion systems, catalytic panels emit low levels of NOx and CO₂, making them environmentally friendly while ensuring consistent performance over long operational cycles.

The heat produced by catalytic panels is transferred through radiation rather than convection, which means the energy is directed straight to the surface of materials. This method minimizes heat loss and maximizes process efficiency, particularly in industrial environments that require stable and uniform temperature distribution.

Energy Efficiency and Reduced Operating Costs

One of the main advantages of catalytic gas radiant panels lies in their energy efficiency. Since the heat is generated directly where it’s needed, these systems reduce energy waste and lower fuel consumption. The catalytic reaction converts gas energy into infrared heat with efficiency levels that can exceed 90%.

Key factors contributing to energy savings include:

- No preheating time: panels reach operational temperature almost instantly.

- Localized heating: only the material or product area is heated, not the surrounding air.

- Reduced maintenance: the absence of moving parts and open flames minimizes wear and tear.

Over time, these features result in substantial cost reductions, especially in high-throughput production lines where energy costs represent a major share of total expenses. Furthermore, companies can achieve measurable improvements in their carbon footprint—a crucial aspect for industries pursuing ISO 14001 or energy efficiency certifications.

Faster Cycle Times and Enhanced Productivity

Catalytic panels are known for their ability to shorten processing times significantly. The infrared radiation penetrates materials quickly and uniformly, enabling faster curing, drying, or heating phases. For example, in paint or coating applications, catalytic heaters ensure rapid polymerization without surface overheating or deformation.

This ability to maintain consistent product quality, even at high production speeds, makes catalytic gas radiant panels an essential element in continuous and automated production lines.

Compared with conventional hot air or convection ovens, catalytic panels can reduce cycle times by up to 50%. The immediate start-up and shutdown capability allows operators to adapt quickly to varying production demands, avoiding energy losses during idle phases.

Safety and Environmental Benefits

Another significant advantage of industrial catalytic heaters is their superior safety profile. Since there is no open flame, the risk of fire or explosion is dramatically reduced, even in environments where volatile compounds (such as solvents or VOCs) are present.

Catalytic technology operates at surface temperatures below the ignition point of most industrial gases, while still achieving the desired heating performance. This makes it suitable for industries that require ATEX or other safety certifications.

In addition to safety, catalytic systems contribute to sustainability. They generate minimal pollutants, and their clean operation supports compliance with increasingly stringent environmental standards. Companies investing in these systems can benefit from lower emissions, reduced ventilation requirements, and an overall greener production process.

Applications Across Industrial Sectors

Catalytic gas radiant panels are used in a wide range of industries thanks to their versatility and adaptability. Among the most common applications are:

- Coating and painting: for rapid drying and curing of paints, adhesives, and protective layers.

- Plastics processing: for thermoforming, preheating, or drying polymer sheets.

- Wood industry: for curing varnishes or adhesives on delicate wooden surfaces.

- Textile and food sectors: for controlled drying or heat treatment requiring hygienic, flameless systems.

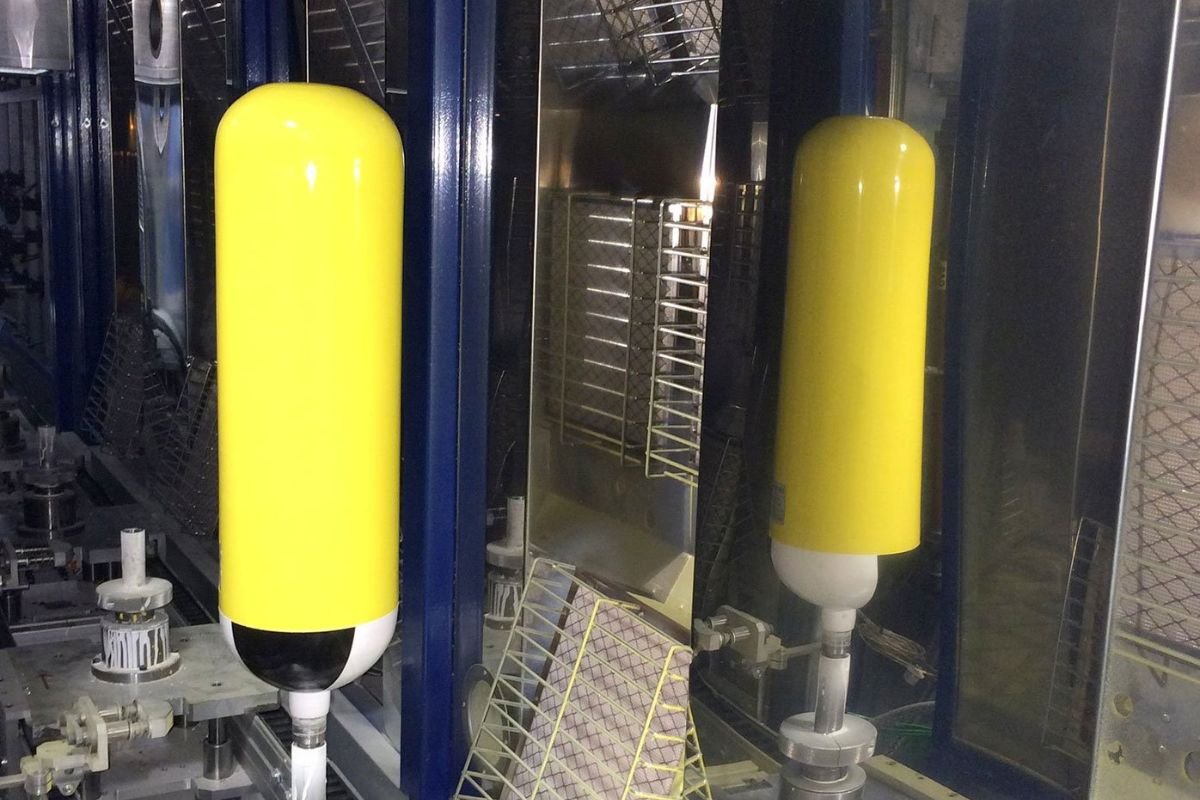

Infragas has developed catalytic heating panels designed to meet the specific demands of these applications, offering modular solutions that can be integrated into both new and existing industrial lines.

Integration with Modern Industrial Systems

Modern production environments require systems that can be easily integrated into automated or digitalized processes. Catalytic panels meet these needs through modular design and compatibility with PLC-based temperature and energy management systems.

This integration not only ensures precise control but also allows for the collection of process data that can be analyzed to further optimize energy efficiency. By combining catalytic technology with smart control, manufacturers gain the flexibility to adjust production parameters in real time, minimizing waste and downtime.

A Technology Shaping the Future of Industrial Heating

The transition toward sustainable manufacturing is driving industries to adopt technologies that combine efficiency, safety, and environmental responsibility. Catalytic gas radiant panels embody these principles by providing a clean and reliable source of heat adaptable to a variety of processes.

As innovation continues, companies like Infragas are refining catalytic systems that deliver even higher efficiency levels, longer service life, and improved thermal performance.

Choosing catalytic heating technology is not only a matter of improving operational performance but also an investment in a sustainable industrial future where energy savings and environmental stewardship go hand in hand.