Hydraulic cylinders sit at the center of heavy machines that power construction sites, factories, farms, and ports. They handle massive loads every day, pushing, lifting, and pressing with steady force while most people barely notice them. Problems only surface when a machine slows down, leaks oil, or stops working entirely. At that point, the cost is not just a repair bill; it’s a significant investment. Lost production time, delayed projects, and safety risks quickly add up. A single failure can shut down operations for hours and create pressure across an entire team. This is why proactive hydraulic cylinder maintenance is the best defense against unexpected downtime.

Many facilities struggle because they are unsure where to start. Basic checks are often skipped, fluid quality is usually ignored, and seals wear out quietly. Without a clear hydraulic cylinder maintenance plan, minor issues stay hidden until they trigger sudden breakdowns. By then, repairs cost far more than routine care ever would.

Maintenance doesn’t have to feel overwhelming. With simple checks, timely testing, and consistent habits, hydraulic systems stay reliable for years. In this article, we break down hydraulic cylinder maintenance, covering the causes of failure, proven inspection methods, and schedules that work on the shop floor.

Understanding Why Hydraulic Cylinder Maintenance Matters

Hydraulic cylinders work in demanding conditions every day, moving heavy loads that would overwhelm most mechanical systems. While they are built for durability, constant pressure, heat, and movement gradually take their toll on them. Without regular care, minor wear and tear quickly turn into severe damage. This is why consistent hydraulic cylinder maintenance plays a crucial role in ensuring equipment reliability, safety, and long-term cost-effectiveness.

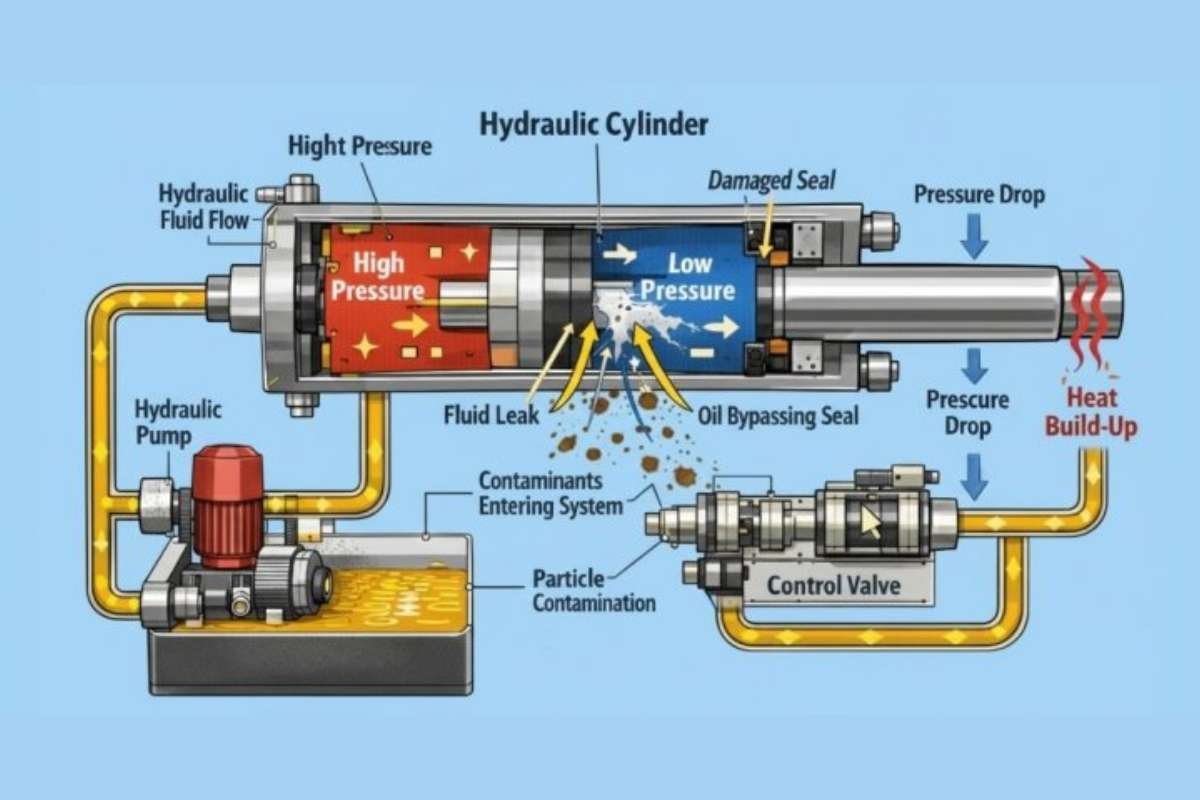

Fluid contamination remains the most common cause of hydraulic cylinder failure, accounting for a large share of system breakdowns across industries. Water, dust, and fine particles often enter through worn seals, neglected fluid changes, or improper handling. Once inside, contamination erodes seals, scratches rods, and causes internal leakage that reduces performance. Even a small, steady leak can waste hundreds of gallons of fluid in a year, increasing operating costs and raising environmental compliance concerns.

Mechanical stress adds another layer of risk. Misalignment and side loading apply uneven forces to the rod and seals, leading to bending, accelerated wear, and eventual failure. These issues often develop slowly and go unnoticed. Hydraulic drift, where a cylinder moves without command, is another warning sign linked to worn seals or fluid breakdown. Temperature extremes worsen all of these problems, making disciplined maintenance essential for long-term system stability.

The Cost of Skipping Maintenance

Here’s what happens when you neglect hydraulic cylinder maintenance: repair bills skyrocket. A basic seal kit replacement runs around $300, while complete rebuilds exceed $5,000. However, the hidden cost, unplanned downtime, is far worse.

Companies implementing predictive maintenance see results:

- 10 to 40 percent reduction in maintenance costs

- 50 percent fewer unplanned outages

- Better planning and resource allocation

Many shops face staffing shortages that make proper maintenance challenging. Over 65 percent of facilities operate with understaffed teams, and technicians are leaving the field at an alarming rate. This means preventive planning becomes even more critical, and you can’t simply call in reinforcements when equipment breaks.

What Actually Breaks Hydraulic Cylinders?

Hydraulic cylinders fail for specific reasons—and most of them are preventable. Understanding these causes helps you catch problems before they become expensive emergencies.

1. Fluid Contamination

Contamination tops the failure list. Water, dust, and particles can enter your system through worn seals and degraded hydraulic fluid. Once inside, contaminants score cylinder rods, corrode metal surfaces, and damage piston seals, creating internal leakage that robs your cylinders of power. This is why fluid testing and filtration matter so much in your maintenance routine.

2. Improper Installation and Misalignment Issues

Poor installation sets cylinders up for failure from day one. When technicians skip alignment checks during mounting, the cylinder rod doesn’t operate straight. This creates side loads that the cylinder wasn’t designed to handle, causing premature wear, bending, and seal degradation. The problem often goes unnoticed until performance visibly deteriorates.

3. Temperature Extremes and Seal Degradation

Hydraulic seals work within specific temperature ranges. High heat degrades seals and causes deformation, while cold makes them brittle and prone to cracking. When seals fail, hydraulic fluid leaks, and your cylinder stops performing. Temperature cycling accelerates seal aging by continuously stressing the material, thereby increasing its degradation rate.

4. Corrosion

Corrosion weakens cylinder walls from the inside out. Rust begins as surface pitting that deepens over time, creating weak points where cracks form under pressure. In worst cases, corroded walls rupture, causing catastrophic failure. Corrosion accelerates in humid environments or when cylinders are exposed to moisture during storage and transportation.

5. Overpressure Conditions

When hydraulic systems exceed design pressure limits, seals are forced out of their grooves, and the stress on cylinder walls exceeds their strength. This often happens when relief valves malfunction or become stuck. A single overpressure event can compromise seals and metal structure in ways that aren’t immediately visible but cause failures later.

6. Rod Bending and Side Load Damage

Rod bending occurs when side loads develop due to misalignment or improper loading. A bent rod creates uneven seal contact, accelerating wear and leakage. You can visually spot a bent rod – one side appears shiny, while the other looks dull and rough. Severe bending reduces load capacity and eventually causes the rod to break completely.

Understanding Your Hydraulic Cylinder Components

You maintain equipment better when you understand what you’re working with. Here’s what every cylinder contains:

- Cylinder barrel – The outer shell holding everything together

- Piston and rod – The moving parts that do actual work

- Seals and gaskets – The critical barriers preventing leaks

- Hydraulic fluid – Transmits power, lubricates, cools, and cleans

- End caps and mounts – Structural support and attachment points

Each component plays a role in your hydraulic cylinder maintenance routine. Neglect any single element, and you’re asking for trouble.

Two Approaches to Maintenance: Choosing What Works Best

Maintenance programs typically follow one of two approaches, each serving a distinct purpose depending on the equipment’s criticality to daily operations.

Preventive maintenance is typically scheduled around fixed intervals. Inspections and service tasks happen at set intervals, regardless of whether a problem is visible. This includes routine leak checks, planned lubrication, regular fluid testing, and scheduled part replacements. The strength of this approach lies in its simplicity. It creates discipline, reduces the chance of overlooked issues, and helps teams address wear before it leads to failure.

Predictive maintenance relies on condition-based monitoring rather than calendars. Sensors track pressure, temperature, vibration, and operational patterns in real-time. When data trends move outside normal ranges, maintenance teams receive alerts and can act before damage escalates. This method minimizes unnecessary servicing and reduces unplanned downtime; however, it requires an investment in monitoring systems and skilled staff to analyze the data.

For most facilities, the best results are achieved by combining both methods. Scheduled maintenance establishes consistency, while predictive tools focus attention on high-value or high-risk equipment where downtime carries serious consequences.

Your Maintenance Schedule for Optimal Results

Implementing a consistent hydraulic cylinder maintenance schedule prevents most hydraulic cylinder problems. Here’s what works in real industrial environments when maintenance is treated as a routine responsibility rather than a reaction to failure.

➤ Daily Checks

Before equipment runs each day, perform quick visual inspections as part of basic hydraulic cylinder maintenance. Look for obvious leaks around seals and connection points. Check the hydraulic fluid levels and note any unusual sounds the system makes when operating. Corrosion developing on cylinder bodies signals moisture issues. These daily habits take only minutes but catch obvious problems before they become serious.

➤ Weekly Tasks

Lubricate pivot points according to manufacturer specifications. Confirm rod alignment and that cylinder mounts remain secure. Vibration during operation can indicate misalignment, so test this regularly. Weekly attention prevents minor issues from festering.

➤ Monthly Inspections

Test hydraulic fluid for contamination levels using appropriate testing methods. A differential pressure gauge on your filter system indicates when filters need to be changed. Inspect all seals and hoses for signs of wear or damage. Monitor system pressure and response time – a slower response can indicate internal leakage or valve problems. Cycle the cylinders fully to prevent fluid stagnation and inspect for any issues with extension or retraction.

➤ Quarterly and Semi-Annual Reviews

Rotate equipment where possible, using spare cylinders to give your regular units rest periods. When cylinders are removed, inspect them thoroughly and replace seals as a preventive maintenance measure. Verify that all accessories, such as clevises, pivot pins, and brackets, are in good condition.

➤ Annual Maintenance

This is when deep maintenance happens. For cylinders under heavy use, perform a complete teardown and inspection. Replace all seals and wear rings, and inspect the pistons and rods closely for damage. Conduct hydrostatic pressure testing, the safest and most comprehensive method available for testing. Fill the cylinder with clean fluid, position the piston at mid-stroke using hydraulic pressure, and monitor both sides for leaks. Flush the entire system and refill with clean, manufacturer-specified hydraulic fluid. Test rod straightness (a bent rod will appear shiny on one side and dull on the other) and address any bending immediately.

Testing Your Cylinders: Three Methods Explained

You need to know what’s actually happening inside your cylinders. Three testing approaches give you different levels of detail.

1. End-of-Stroke Bypass Test

This pressurizes the cylinder at full extension and retraction to detect seal leakage. It’s straightforward but only tests seals at stroke endpoints where wear is typically minimal. The center of your cylinder tube, where the most severe wear commonly occurs, doesn’t get thoroughly tested.

2. Mid-Stroke Bypass Test

This evaluates piston seal integrity where wear is most severe. But here’s the problem: it’s dangerous. Even small cylinders generate forces of 6 to 10 tonnes. Larger cylinders make this test practically impossible to perform safely.

3. Hydrostatic Testing (The Smart Choice)

This is the safest and most comprehensive approach. You secure the cylinder, fill both sides with clean hydraulic fluid, connect the control valves and relief valves, and remove air by cycling the system. Position the piston rod at mid-stroke, close the ball valves, and direct the fluid flow to the rod end while increasing the pressure. Monitor gauge readings for any changes that indicate leaks. This method protects your team and equipment while providing accurate results.

Six Critical Annual Maintenance Tasks

Not all maintenance work carries equal importance. These six tasks form the backbone of solid hydraulic cylinder maintenance:

1. Rod Quality Check

Bent rods cause load shift and degraded performance. Check for excessive roughness that creates seal leakage; rod diameter and strength are crucial for load-bearing capacity.

2. Seal and Valve Inspection

Piston seals and rod seals prevent leaks and cylinder drift. The holding valve must function correctly. Visual inspection catches hardening, cracks, or deformation.

3. Fluid Conditioning

Aerated fluid creates noise issues and performance problems. Use high-efficiency filtration and replace filters before they bypass. A clogged filter that stops working defeats the purpose entirely.

4. Cylinder Tube Examination

Look for ballooning when the tube wall stretches outward. This typically occurs when walls are too thin or when pressures exceed the material’s strength. Ballooning allows fluid to pass through seals and invites contamination.

5. Rotation of Spare Cylinders

Keep cylinders fresh by rotating through your system. This allows for the inspection of hydraulic circuits when equipment is disassembled and provides primary cylinders with rest periods.

6. Accessory Inspection

Check clevises, ball joints, brackets, and rod eyes for proper alignment. Worn accessories cause slop and play that lead to misalignment. Visible play between joints signals that service is needed.

When to Fix It Versus Replace It?

Not every problem requires replacing your cylinder. Here’s when to repair and when to replace:

Repair when:

- Seals and gaskets are worn

- Minor rod bending can be straightened with a hydraulic press

- Chrome coating remains intact on rods

- Minor surface scratches need polishing

Replace when:

- Barrel walls are cracked (safety hazard)

- Rod bending is severe and cannot be safely straightened

- The cylinder keeps failing despite multiple repairs

- Repair costs exceed 60 percent of a new cylinder’s price

That last point matters. Beyond direct cost, consider reliability. A repaired cylinder with questionable integrity incurs additional fees, considering potential future breakdowns and lost production.

Environmental and Regulatory Reality

Your hydraulic cylinder maintenance practices now carry legal responsibility. Regulators are serious about spills. One recycling facility received a $14,000 fine for failing to report a 50-gallon spill of hydraulic oil. Companies must document spills, use certified containment kits, and switch to biodegradable fluids where feasible.

If you’re transitioning to eco-friendly hydraulic oils, verify compatibility with all seals and components first. Incompatible fluids can degrade seals and cause failures. Develop and maintain spill response procedures, it protects your operations and the environment.

Technology Advances in 2026

Smart cylinders with embedded sensors are transforming the way maintenance is conducted. Condition-based alerts inform you precisely when service is required. Cycle tracking identifies high-use components before they fail, allowing for proactive maintenance. Pressure profiling detects overload patterns that indicate problems.

However, these systems introduce cybersecurity risks and require trained personnel to interpret data. Adoption remains strongest in sectors where uptime is mission-critical, such as mining, defense, and aerospace. For most operations, innovative technology works best in conjunction with traditional preventive maintenance.

Conclusion

Hydraulic cylinder failures often develop over time due to contamination, seal wear, misalignment, and temperature stress. When these warning signs are left unchecked, breakdowns can occur suddenly and be costly. A consistent hydraulic cylinder maintenance routine prevents this by identifying issues early and reducing unplanned downtime. Regular inspections, proper testing, and timely repairs ensure equipment remains reliable and safe across various industrial applications. In 2026, disciplined maintenance is crucial for controlling costs, enhancing uptime, and ensuring hydraulic systems operate as expected under demanding conditions.