In a demonstration of how AI CNC programming is transforming manufacturing, a neural network autonomously generated G-code for a five-axis machining center, it was observed that what previously required hours of meticulous work by a process engineer, the machine delivered in just a couple of minutes. The trajectory quality was found to be superior to that of an experienced programmer.

This illustrates the reality of modern manufacturing, where artificial intelligence is fundamentally transforming the approach to CNC machine programming.

The Current State of AI in Manufacturing

Most manufacturing companies continue to program machines using traditional methods, where a process engineer manually selects machining strategies and adjusts cutting parameters.

However, change is occurring. According to McKinsey’s 2024 research, 37% of industrial enterprises in developed nations have already integrated machine learning elements into their production workflows. In the US, that number reaches 42%, while Europe is at approximately 34%. This trend is clear.

How AI CNC Programming is entering a domain previously considered impervious to automation. CNC programming has historically been viewed as a creative endeavor requiring years of experience and intuitive understanding. It is now evident that machines can also master this process.

A CTO of a major aerospace manufacturer noted that their millennial engineers readily adopt AI assistants, while seasoned veterans maintain a “cautiously optimistic” stance.

Why This Matters Now?

The manufacturing landscape is undergoing significant shifts due to:

- Skilled worker shortage: Baby boomers are retiring at a faster rate than replacements can be trained.

- Complexity explosion: Parts are becoming increasingly intricate.

- Cost pressures: Global competition necessitates maximum efficiency.

- Quality demands: Zero-defect manufacturing is becoming standard.

Machine Learning for Intelligent Tool Path Optimization

Traditional CAM systems rely on rigid, pre-programmed algorithms, which are functional but not always optimal. Machine learning enables intelligent trajectory generation.

In such a scenario, a neural network analyzes thousands of successful machining programs, considering workpiece material properties, part geometry complexities, machine-specific characteristics, and environmental factors. From this extensive dataset, it generates trajectories that minimize cycle time while maintaining or improving surface quality specifications.

Adaptive Feed Control: The Game Changer

Adaptive feed technology showcases how AI CNC programming can dynamically adjust feed rates in real-time based on instantaneous tool loading conditions, eliminating the need for conservative programming to avoid tool breakage.

Real-world impact:

- 25-40% reduction in machining time

- 30-50% improvement in tool life

- Consistent surface finish across varying geometries

- Reduced operator intervention requirements

The system learns optimal cutting conditions through continuous feedback loops, accelerating through easy sections and intelligently slowing down when encountering challenging geometries.

A Quick Reality Check

These systems require a “learning period” on specific machine-material combinations. The initial parts necessitate close supervision, but once trained, the AI operates with considerable autonomy.

Predictive Analytics: The Crystal Ball of Manufacturing

Machines are learning to predict failures before they occur. This is currently being implemented in factories worldwide.

1. How It Actually Works?

These systems continuously monitor hundreds of sensor inputs:

- Vibration signatures from spindles and axes

- Temperature fluctuations across critical components

- Power consumption patterns from drive motors

- Acoustic emissions during cutting operations

- Dimensional drift in finished parts

Neural networks identify subtle pattern changes that human operators cannot detect. For instance, a barely perceptible shift in spindle vibration characteristics might indicate bearing degradation weeks before critical failure.

2. The Business Impact is Staggering

A maintenance manager at a Tier-1 automotive supplier reported initial skepticism when the system flagged a seemingly healthy spindle for bearing replacement. Upon inspection, the race showed signs of distress. This early warning prevented a $50,000 unplanned downtime event.

Quantified benefits:

- 70-80% reduction in unplanned downtime

- 20-30% decrease in spare parts inventory costs

- 40-60% improvement in maintenance scheduling efficiency

- 15-25% extension in overall equipment effectiveness (OEE)

3. Investment Considerations

Implementing comprehensive predictive analytics requires substantial upfront investment in sensor infrastructure and edge computing hardware. However, most manufacturers observe ROI within 12-18 months.

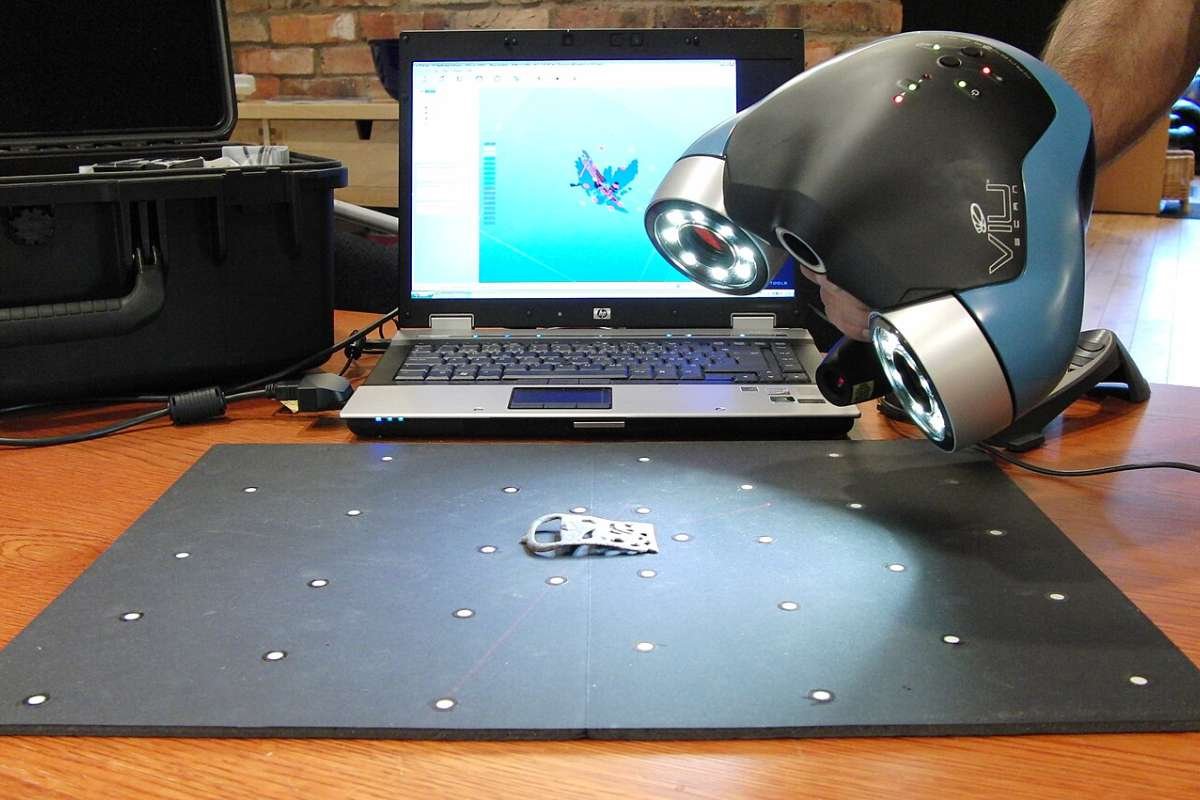

AI-Driven G-Code Generation: Programming Reimagined

Automated control program generation represents a transformative AI application in CNC manufacturing.

1. The Magic Behind the Curtain

Modern AI systems analyze a 3D CAD model and autonomously generate complete machining programs, including tool paths, optimized cutting parameters, tool selection, and fixture requirements. The process considers:

- Machine-specific capabilities and constraints

- Available tooling inventory and condition

- Material properties and machinability ratings

- Surface finish specifications and tolerance requirements

- Production volume and batch size considerations

2. Real-World Application

The workflow involves uploading a CAD model, specifying material and quality requirements, and receiving a production-ready program within minutes. Often, these AI-generated programs outperform manually created ones.

Where it excels:

- Repetitive geometries: Housings, flanges, brackets

- Standard operations: Drilling patterns, pocket milling

- Material-specific optimization: Titanium, composites, hardened steels

Current limitations:

- Complex, one-off parts still require human expertise

- Non-standard tooling may confuse the algorithms

- Extreme precision requirements need manual verification

Even for unique applications, how AI CNC Programming provides an excellent starting point that process engineers can refine, significantly accelerating programming cycles.

Neural Network Integration with CAD/CAM Ecosystems

The primary challenge in AI adoption is seamlessly integrating smart algorithms with existing CAD/CAM infrastructure. Most shops have heavily invested in specific software platforms, making wholesale system changes economically prohibitive. For those new to the field, understanding what CAM software is provides essential context for appreciating these AI-powered advances.

1. The Plugin Revolution

Developers have adopted modular integration approaches, delivering AI capabilities as plugins for established platforms:

- Mastercam: AI-powered toolpath optimization modules

- Siemens NX: Machine learning-enhanced CAM strategies

- Autodesk PowerMill: Intelligent parameter recommendation engines

- CATIA: Neural network-driven process planning tools

2. Hybrid Intelligence: The Sweet Spot

The most successful implementations combine human creativity with machine optimization:

- Human-led approach: Engineer creates base strategy → AI optimizes parameters

- AI-led approach: System generates initial program → Engineer refines specifics

- Collaborative mode: Real-time suggestions during manual programming

3. Enterprise Integration Requirements

For maximum effectiveness, AI systems need integration with:

- MES platforms: Real-time production scheduling data

- Tool management: Availability and condition monitoring

- Quality systems: Feedback for continuous improvement

- ERP systems: Cost tracking and resource allocation

Modern CNC programming solutions increasingly demonstrate how AI CNC Programming incorporate machine learning elements that streamline routine operations while enhancing overall production efficiency.

4. Cloud-Based Solutions: Democratizing AI

Cloud-deployed AI enables smaller manufacturers to access sophisticated machine learning capabilities without massive infrastructure investments. Pay-per-use models are making advanced optimization accessible to job shops and mid-size manufacturers.

Implementation Results and Future Horizons

An examination of what is currently working and future projections.

Proven Results from Early Adopters

Companies successfully implementing AI in CNC programming report impressive metrics:

| Metric | Improvement Range | Typical Payback |

| Programming time reduction | 40-60% | 6-12 months |

| Machine utilization increase | 25-35% | 8-14 months |

| Tool life extension | 20-30% | 4-8 months |

| Quality defect reduction | 15-25% | 10-16 months |

| Overall productivity gain | 30-45% | 12-18 months |

The Learning Curve Reality

These results are not achieved instantaneously. Typical implementation timeline:

- Months 1-3: System installation and initial training

- Months 4-6: Fine-tuning and process optimization

- Months 7-12: Full capability realization and ROI achievement

- Year 2+: Continuous improvement and capability expansion

What’s Coming Next?

Industry experts project several breakthrough developments by 2030:

- Generative Manufacturing Design AI will design components from scratch based on functional requirements, manufacturing constraints, and cost targets.

- Autonomous Production Cells Complete lights-out manufacturing where AI manages everything from order intake to finished goods shipping.

- Digital Twin Integration Real-time synchronization between physical machines and virtual models for predictive optimization.

- Cross-Domain Learning AI systems that learn from multiple industries and manufacturing processes, accelerating optimization across diverse applications.

The Skills Evolution Challenge

Workforce transformation is a key consideration in how AI CNC Programming is reshaping the industry. Process engineers will not become obsolete, but their roles will evolve-from manual programming to training and overseeing AI systems.

New skill requirements:

- Data interpretation: Understanding AI recommendations and limitations

- System training: Teaching machines optimal practices and constraints

- Exception handling: Managing edge cases where AI struggles

- Continuous improvement: Refining AI performance through feedback loops

The Bottom Line: Adapt or Fall Behind

Ignoring AI in manufacturing is becoming a luxury few can afford. Competitors leveraging these technologies gain substantial advantages in speed, quality, and cost efficiency.

The question is not whether to implement machine learning, but when to start and how aggressively to pursue adoption.

It is recommended to start small with pilot projects on repetitive, high-volume parts and gradually build internal expertise. Starting now is crucial, as the learning curve is steep, and competitive advantages compound over time.

The future of CNC programming is here, driven by how AI CNC Programming is reshaping the industry. The only question is whether organizations will lead the charge or play catch-up.