As 3D Scanning Technology infiltrates our everyday lives, things that were once in the realm of science fiction have now become to resemble reality. Take, for example, the replicator from the acclaimed Star Trek franchise. In the 1960s, no machine existed that could create a replica of an object – at that point, computing was in its infancy.

Over the decades since, however, technology has evolved in a very drastic sense. 3D scanning in Australia has experienced rapid technology improvements, as well as parallel developments in 3D printing. This has resulted in the rapid implementation of 3D technology in fields such as aerospace and medicine, and rarely supplied with a true appreciation of the scale and scope of underlying technologies.

Let’s take a moment to discover the wonders of 3D scanning technology, one vital component of the 3D design and development industry, and just how it can be applied to make waves in today’s rapidly developing world.

How Does 3D Scanning Work?

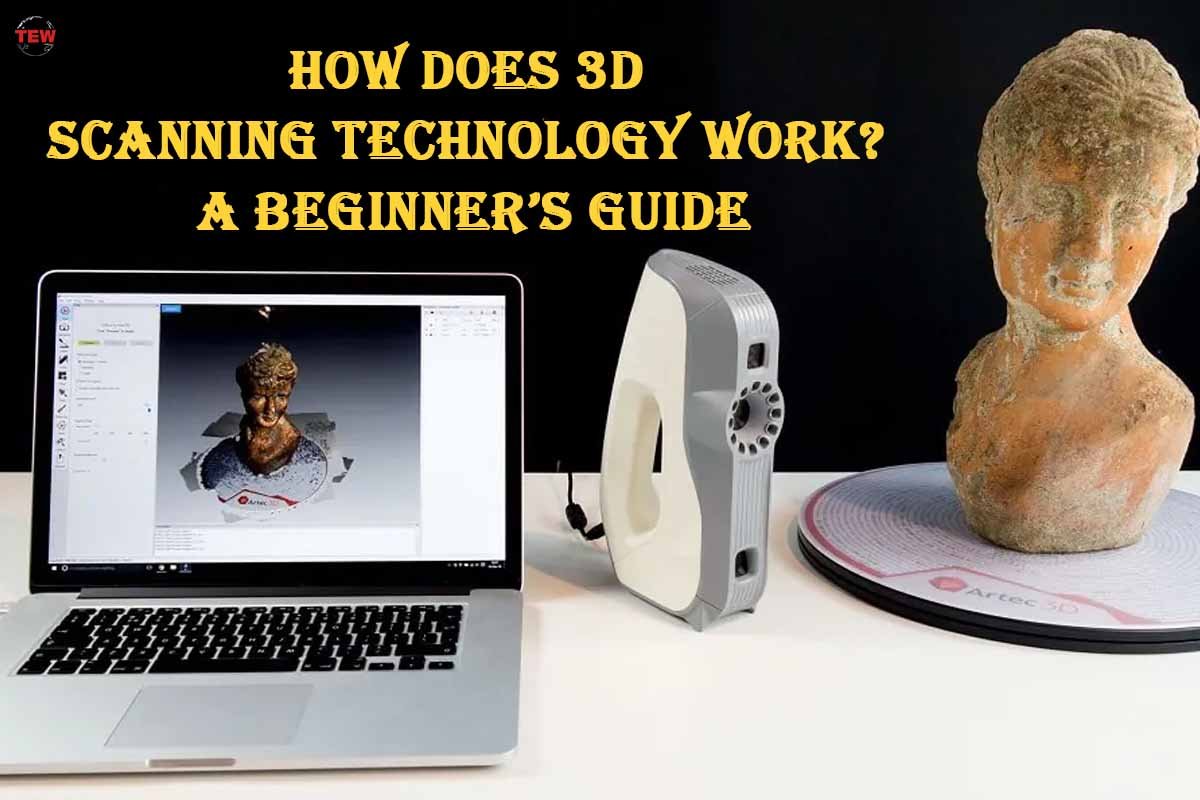

3D Scanning Technology seems like a relatively straightforward process. Simply put, it uses one of any number of sensors to get a picture of a 3D object. Depending on the object being scanned, and the lighting and material conditions available, a 3D scanning specialist may choose to use multiple different types of 3D Scanning Technology to get the most accurate possible representation, or 3D model, of your item.

Depending on the type of scanning being done, each type of scanning can have an effect on the object or material. In fact, if your material is particularly sensitive, some types of scanning can be outright damaging to materials and surfaces.

Choosing the right type of 3D Scanning Technology for your needs is essential to keeping costs to a minimum, and ensuring you get the highest quality scans possible for your needs.

Types of 3D Scanning Technology :

There’s a diverse range of 3D scanning technologies, no matter what your item is made of, and where it’s located. These technologies vary in quality, the time required, and depending on the method, may have different impacts on the item you’re scanning. Let’s explore a few of the different types of 3D scanning methods that are used today.

1. 3D Photo Scanning (Photogrammetry)

Photogrammetry is one of the cheapest forms of 3D Scanning Technology – by taking a series of pictures of an object, and running them through specialty software, a 3D mesh of an object can be generated.

While this can be handy for objects that are large, and in open spaces, it can sometimes be difficult to get enough significant detail out of a series of 2D images.

2. 3D Laser Scanning

In 3D Scanning Technology , there are two types of laser-based scanning – those based on time of flight, and those based on the distortion of light around an image. Time of flight scans, also known as 3D laser scanning, typically fire a laser at a fixed object and calculate the time it takes for the laser to return to the object.

While this can be handy in some instances, the technology has drawbacks. For example, lasers don’t function very well in bright light, impeding the quality of 3D scans. Additionally, a lot of 3D laser scanners rely on expensive scanning technology, which can be financially straining on a project.

3. Structured Light Scanning (SLS)

Structured Light Scanning offers users the capacity to get high-precision scans of regular-sized objects. The technology itself is fairly straightforward – light patterns are fired onto an object, and sensors then capture the distorted light patterns to form a model of the object. It’s a great way to get a scan of a small object – however, much like Laser Scanning, sometimes it’s an expensive option for your project.

Computerised Tomography (CT) Scanning

Computerised Tomography involves taking a series of 2D snapshots of different sections of an object, which is sometimes known as segmentation. Once this is done, these images are then stitched together to form a 3D Scanning Technology model. This can be handy in hospitals, where you may wish to obtain a scan of internal injuries.

This type of scanning comes with the risk of being exposed to ionising X-Ray radiation, while also being restricted in what can be fit into a CT scanner. While a CT scanner has some obvious benefits, it’s often considered too expensive and too risky for most scanning needs outside of the medical industry.

Now that you’ve learned about 3D Scanning Technology , where will you take it? Hopefully, this piece will have informed you a little bit more about how 3D scanning technologies are shaping the world we live in today, and how they might just be able to benefit you in your next project.