In heavy industries, lubrication is at the center of asset management and maintenance. Friction reduction is a reliable way to extend the lifespan and efficiency of machinery, while advanced systems are the best defense against thermal stress. A lubrication failure is often the catalyst for prolonged downtime.

RIVI’s custom engineering philosophy

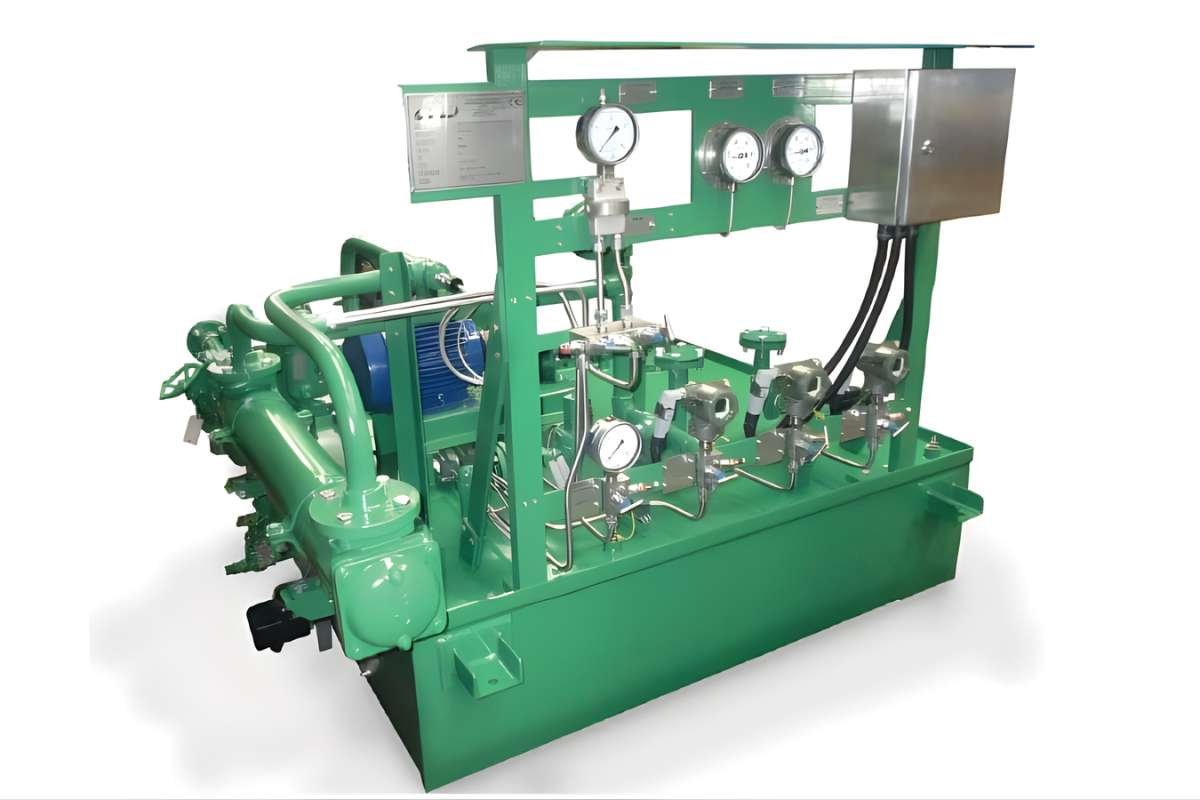

RIVI Technical Group is an example of rejecting the industry’s tendency toward blind standard solutions and instead operates on a philosophy of engineered-to-order precision. This means acknowledging that a paper mill has very different needs to a turbine in a corrosive marine environment. RIVI, when designing special oil circulation systems, caters to extreme temperatures and varying pressures, even in tight space restrictions.

Their engineering depth becomes clear in applications like their feed water pump units for thermal power stations. They’re the opposite of generic pumps – instead they’re fully integrated systems with stainless steel enclosures, dual redundant pumps, programmable logic controllers, and more. By integrating tech like variable frequency drives (VFDs) and double filtration for the contaminated oils, they can make sure the system adapts to the machinery rather than the other way around.

The API standard advantage

For the Oil & Gas sector, reliability is almost always defined by the adherence to American Petroleum Institute standards. RIVI differentiates itself here – instead of just boxing-ticking the criteria, they try to embody such strict parameters. They specialize in API 614 and API 610 compliant solutions.

Their expertise goes deep into API 682 Seal Plans, which are central in preventing hazardous leaks in mechanical seals. RIVI implements sophisticated arrangements like Plan 53B (utilizing a pressurized barrier fluid with a diaphragm accumulator) and Plan 54 (external pressure circulation). It’s this level of technical fluency that makes sure assets like centrifugal pumps and turbomachinery tick over with a safety net – generalist lubrication providers cannot engineer this level of precision.

The 360º service model and varnish removal

RIVI lubrication systems are not internally viewed as if they’re a sunk cost. Instead, it’s an investment that pays ongoing dividends – but equally, it requires an ongoing service. This is where the 360º Service model comes in, as it brings value in the form of lifecycle management. They serve as official dealers for Lincoln and partners for SKF.

One offering worth exploring is their varnish removal service. Varnish is the byproduct of oil oxidation and it slowly kills hydraulic systems – it clogs valves and blunts cooling efficiency. RIVI implements chemical and physical cleaning tech that can strip these residues without disrupting the operations. When you combine this with their ability to design fluid gas treatment skids and interconnection piping, it shows that RIVI indeed achieves to maintain the total health of the industrial fluid circuit. The goal here is to extend the lubricant’s life (and the machine itself).

Intelligent monitoring

Modern industry has moved into Industry 4.0. This new industrial wave has been about implementing IoT and growing the amount of data that is collected and analyzed. RIVI helps achieve this by moving away from manual checks and instead has sensors for temperature, ISO cleanliness, pressure, and more. The data accumulates into a clear picture of the health status and when maintenance is soon to be required. This predictive nature makes it less of a scramble and slashes downtime.

RIVI Technical Group turns lubrication from a consumable utility into an asset with a positive return on income. Bespoke engineering according to a strict regulatory compliance helps them secure the operational continuity of the world’s most demanding machinery.