Modern manufacturing in sectors like electronics, medical devices, and aerospace relies heavily on the precise handling and layering of materials, particularly wires, fibers, and films. Any lack of consistency in this process can lead to defects that compromise the function, efficiency, and safety of the final product.

From micro-coils in hearing aids to heavy cables in transformers, the integrity of the finished component is directly related to how materials are managed during the initial assembly stage. Imperfect layering, uneven tension, or incorrect spacing introduces systemic weaknesses into the product.

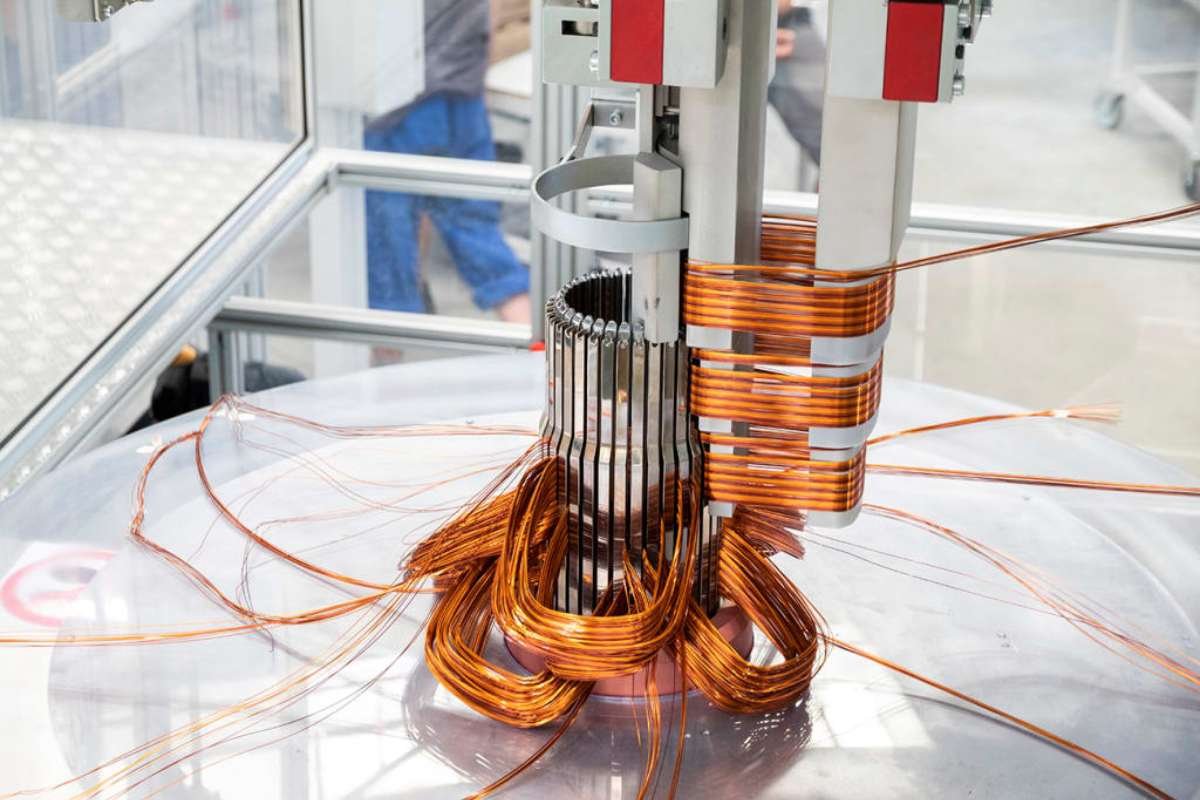

Achieving the required level of dimensional stability and electrical performance demands dedicated, high-accuracy machinery. The specialized requirements for intricate material placement are met by advanced winding systems, which are the backbone of precision component fabrication. These systems enable consistent results at scale, ensuring components meet tight tolerances and performance specifications across production runs.

The Role of Tension Control

Consistent tension is perhaps the most critical variable in any winding application. If the tension is too loose, the material may layer unevenly, leading to gaps, vibration, and instability in the final coil or roll. If the tension is too tight, it can stretch the material, potentially damaging insulation or reducing the material’s structural integrity.

Precision winding systems employ sophisticated feedback loops and electronic brakes to maintain tension within extremely narrow tolerances, often down to a fraction of a gram. This level of control is essential for preventing material fatigue and ensuring optimal electrical or mechanical performance.

For wire winding, consistent tension guarantees uniform wire placement and density. This uniformity is vital for creating coils with exact inductance and resistance characteristics, which is mandatory for electronic components used in critical applications like medical implants or automotive sensors.

Integration With Production Lines

Modern winding equipment is not standalone; it is designed to integrate seamlessly with broader, highly automated production lines. This integration allows for rapid material feeding, automatic termination, and smooth transition to subsequent processes like encapsulation or curing.

The machines often utilize computer numerical control (CNC) programming to execute complex patterns with absolute repeatability. This digital control is essential for high-volume manufacturing where every single component must adhere to a strict blueprint across thousands of cycles.

Effective integration maximizes overall throughput by minimizing the need for manual intervention and reducing potential human errors. The winding process becomes a secure, predictable link in the chain, capable of operating continuously while maintaining top-tier quality standards.

Material Handling and Quality Control

Winding systems must be capable of handling a vast array of materials, from delicate fibers measured in microns to robust films and wires. The handling mechanism must be precisely tuned to the material’s fragility and thickness to prevent any damage during the high-speed process.

Integrated sensor systems perform real-time quality checks, monitoring for layer deviation, wire breaks, or insulation defects. These systems automatically halt the process or flag the component, preventing flawed parts from moving further down the costly production line.

The ability to maintain consistent quality assurance directly impacts the finished product’s reliability. By ensuring uniform density and layer-by-layer precision, winding systems directly contribute to the electrical efficiency and thermal performance of items like electric motors and specialty capacitors.

Customization for Different Applications

The requirements for winding a medical catheter thread are vastly different from those for winding a power transformer core. As such, winding systems are highly modular and customized, allowing engineers to configure them for specific geometries and material properties.

Customization includes specialized traverse mechanisms to handle different coil shapes, unique material guides to prevent abrasion on sensitive films, and targeted heating or cooling elements to set the material in place immediately after winding.

This adaptability allows manufacturers to scale up production of highly specialized, low-volume components using the same foundational equipment. The capacity to fine-tune pitch, angle, and tension enables the creation of products that meet highly specific performance criteria.

Supporting Efficiency and Repeatability

The economic benefit of advanced winding lies in its extraordinary efficiency and repeatability. The high degree of automation minimizes material waste and drastically reduces the labor required per unit, translating directly into lower manufacturing costs.

Crucially, repeatability ensures that the first component produced is functionally identical to the ten-thousandth. This consistency is mandatory for regulatory compliance and essential for ensuring consumer trust, especially in high-stakes industries where failure is not an option.

By relying on tightly controlled electronic and mechanical processes, modern winding systems remove variability from the core manufacturing step. They provide a foundation of reliability, allowing manufacturers to optimize other stages of production with confidence.

Read Next: How the Vending Machine Working Process Powers Modern Convenience in 2026 and Beyond?